what is 3d inspection?

Inspection is a comparison of a set of ideal or required measurements (reference data) to a corresponding set of measurements from the part to be inspected (test data).

The reference data may come in the form of a table, with values at specific points or features, a cad model, or 3d scan. 3D inspection services may require datum measurements, where the part to be inspected is located in a fixture that is specifically designed to orient the part by an ordered method. In some cases, the part may have features that are designed specifically to be referenced by datums, if no functional feature of the part provides a clear reference.

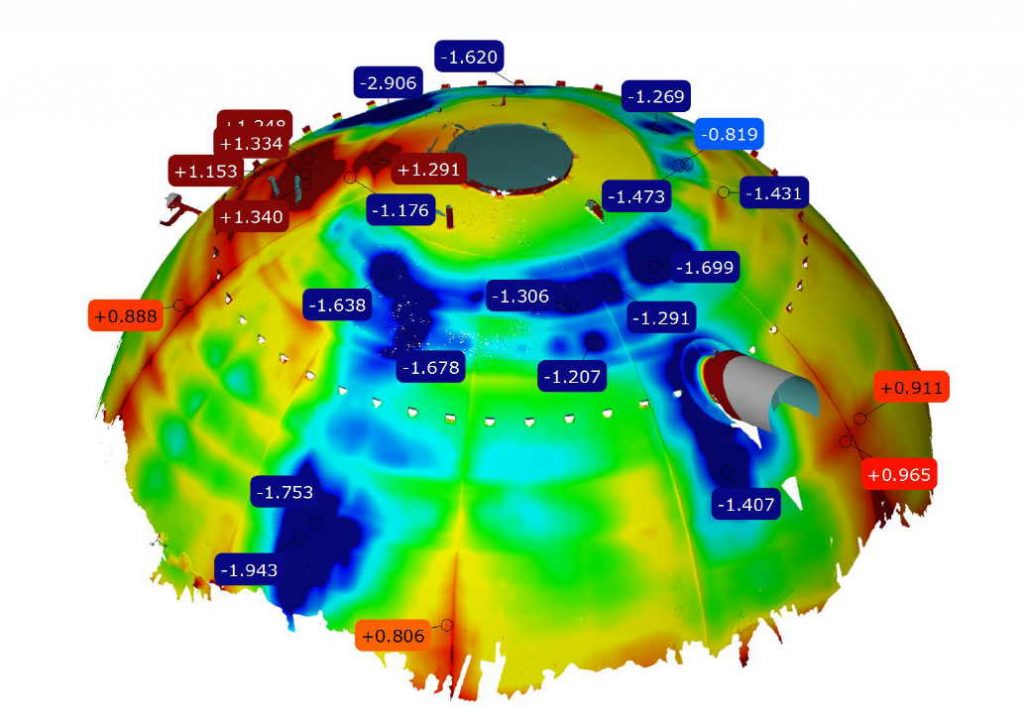

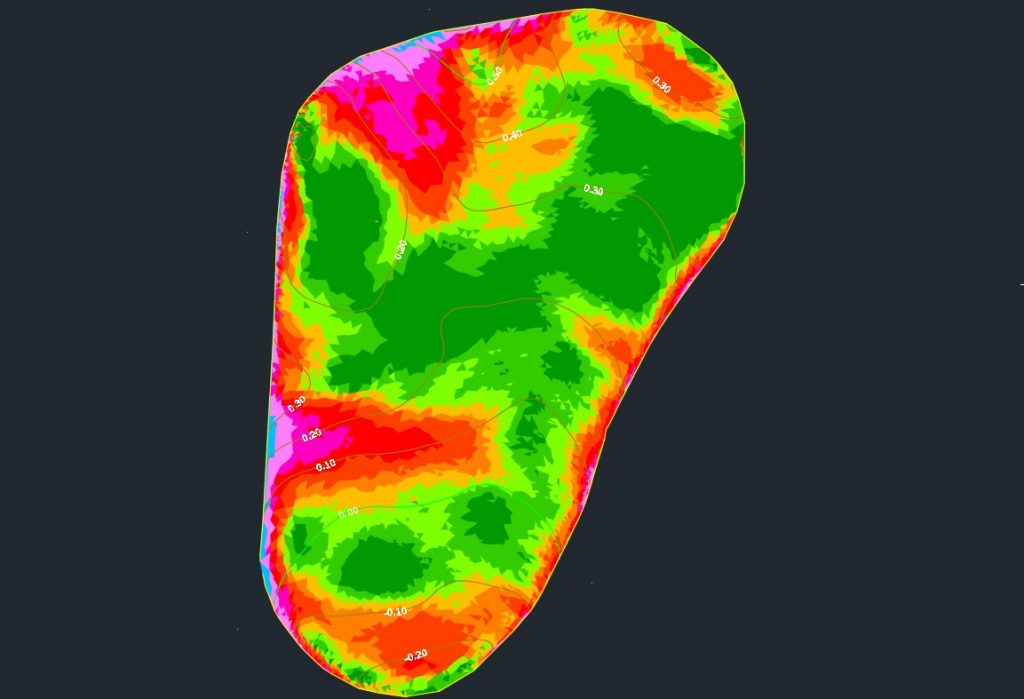

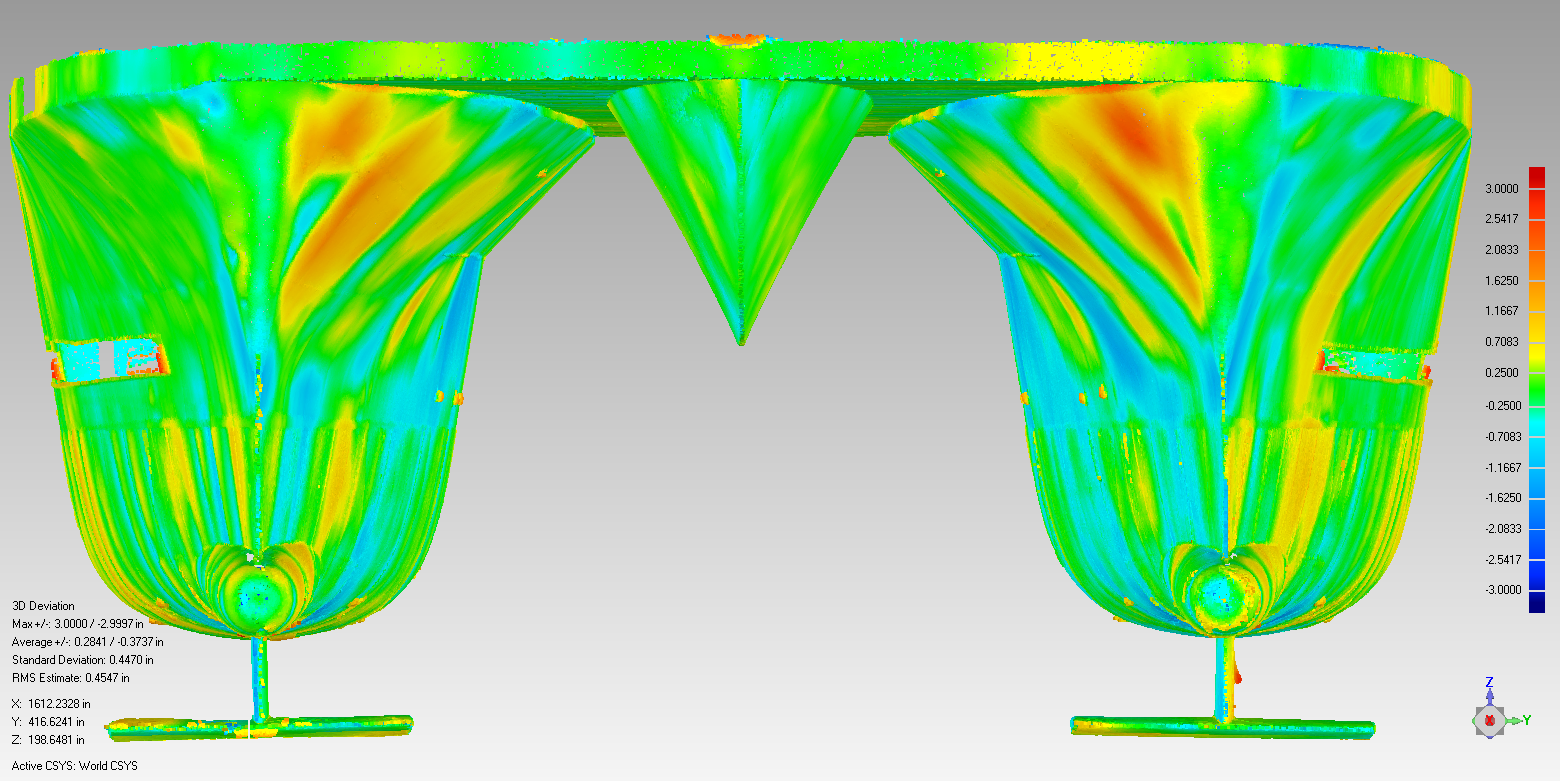

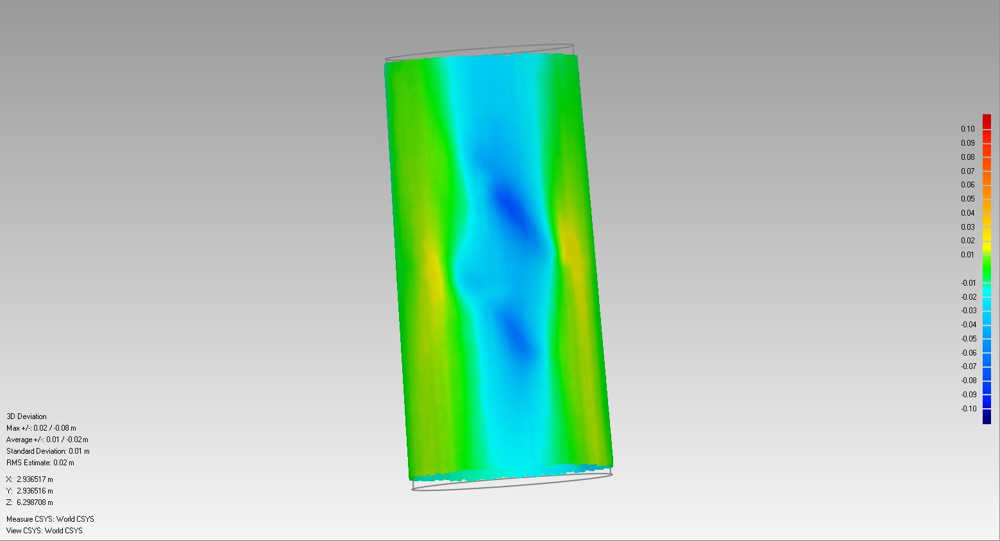

A variety of different scanners can be used to accurately capture the geometry of the part to be inspected. Inspection software is then used to generate measurements from corresponding points or features, or for an entire surface. The results can be in tabular form or a deviation image, depending on the requirement.