Another Day, another challenge

Challenge accepted

The scanning engineer and the 3D FARO laser scanner was put to the test when Arrival3D was required to scan a basement crawl space at a hospital in San Antonio, Texas. It was a return to a hospital central plant that we had scanned previously, which you can read about here. Was the staff at Arrival 3D happy to return to our customer in San Antonio? Absolutely! Did the staff know what was in store for them there? Absolutely not! This was due to the fact that even client did not know what conditions to expect below the floor. From the information given, the floor height from the roof to the ground is approximately 4-5 feet. Seems like tolerable from the information given even though it means bending for the most part.

Additional scans!

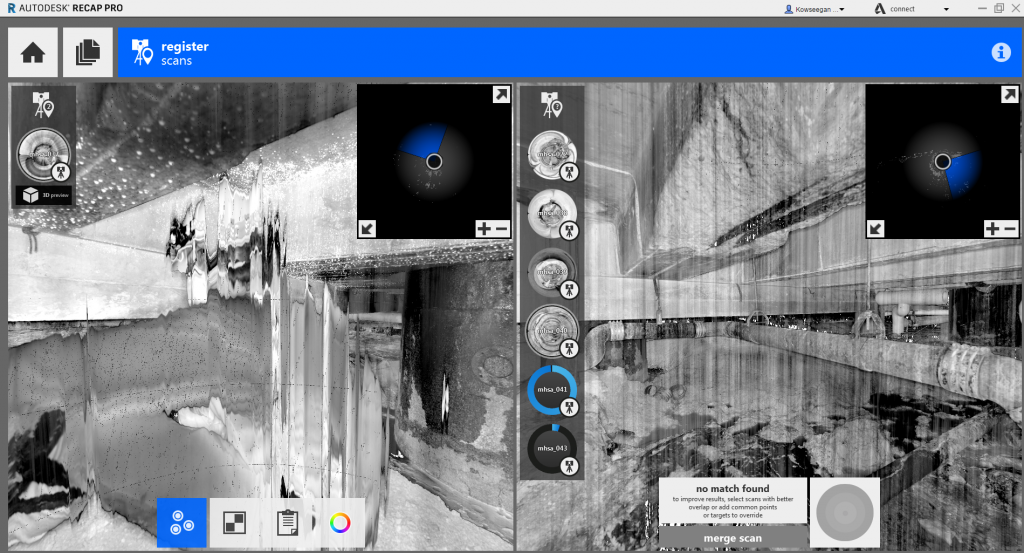

The entire perimeter from ground and above were previously scanned back in February. The client needed additional scans at the basement to visualize the pipe run and generate 3D model of the region. Anyway to cut to the chase, on the day of the scan, the hospital staff and the engineer took almost 15 minutes to figure out a path that would lead to the basement. Finally; when we got to the basement, were we surprised? YES (A BIG YES) the basement did not have any lighting, the ground was muddy from the steam of the boiler, and there was hardly any room to maneuver. The engineer was caught off guard as they did not have the essential tools such as flashlight, mask, knee pads, and etc…

The main concerns for this project:

- Confined area

- Steam that might disrupt the scanning quality and outcome.

- Water dripping from the roof which is a hazard to the Faro 3D scanner.

- Uneven ground which can affect the scanning quality.

There were pipe runs ubiquitously and the engineer had to crawl throughout the entire area while enduring the heat and steam. It was certainly a challenge to find the right setup for the scanner while navigating between pipes. On a usual day, 60 or more scans can be completed for an area of the same coverage however; for this particular project, only 30 scans were done. Each setup took between 10 – 15 mins.

So did we manage to cover the entire basement? Absolutely….not.

Despite the challenges, the engineer managed to scan half the basement in about 8 hours. Did I hear you say “why half”? Well, the other areas were not accessible and the atmosphere was definitely not appropriate for the scanner.

The scanning engineer’s priority for this project were:

- Making sure the scanner is safe.

- Covering as much area as possible.

- Making sure each scan is quality oriented.

Just scanning a perimeter is an easy task; however, ensuring quality is equally important. A poorly planned scan can result in it being unusable. In conclusion, the scanning engineers at Arrival 3D are willing to go to great lengths to get you a quality scan. This project had proven to be tough but exciting which enhanced the scan engineer’s experience.