3D Digital Twin

Digital Twins are expected to become an integral part of Industry 4.0, with Gartner predicting that the Digital Twin market will reach US$183 billion in revenue by 2031.

It is expected that Digital Twins will permeate many different domains, ranging from aerospace, to manufacturing, and even shopping. It’s fair to say that the term is going to become ubiquitous over the coming decade.

So if you are new to the topic of Digital Twins, then welcome to our primer article, in which we will explain what a Digital Twin actually is, and what they are used for.

Get A Free Quote

What is a digital twin?

Digital Twins were first developed by the aerospace industry in the 1960s, but they have become far more complex in the last decade, largely thanks to the growth of enabling technologies such as IoT, Big Data, edge computing, and embedded systems.

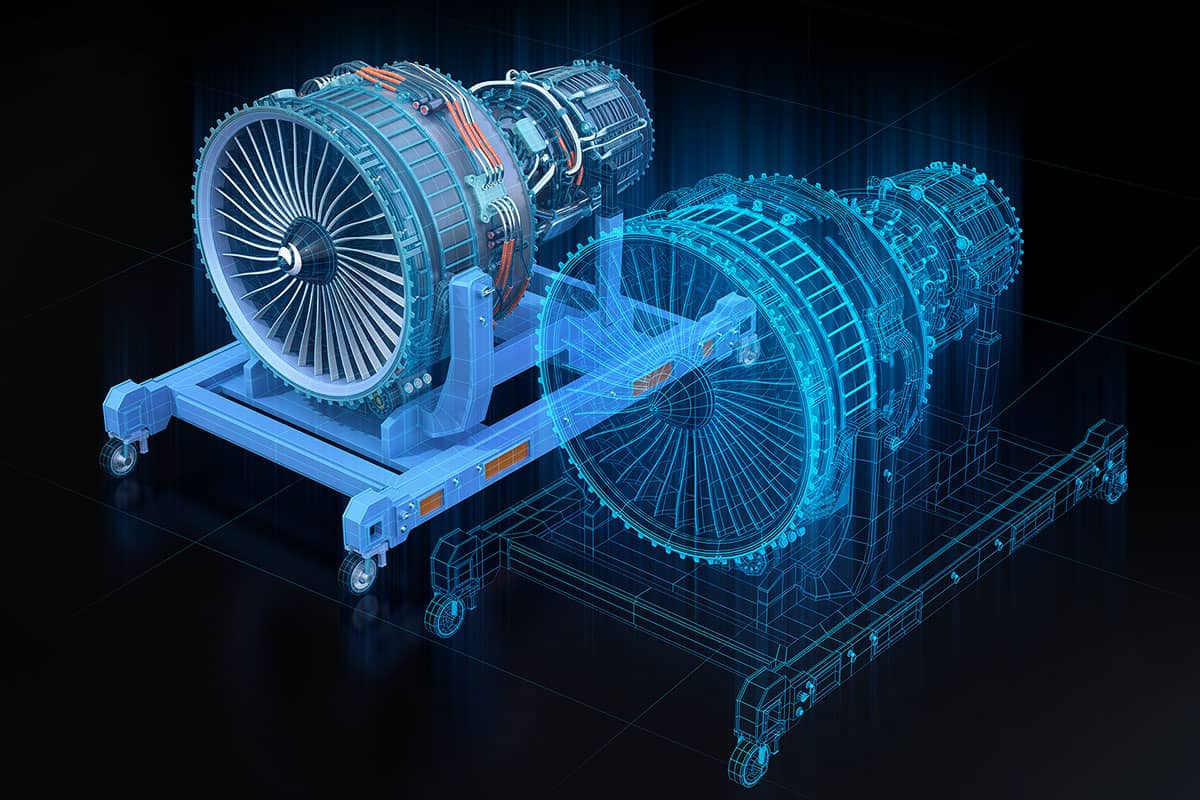

They can come in many forms, ranging from 3D representations of physical hardware assets (such as a jet engine, or a building), to 2D representations of systems such as a map of a water supply network.

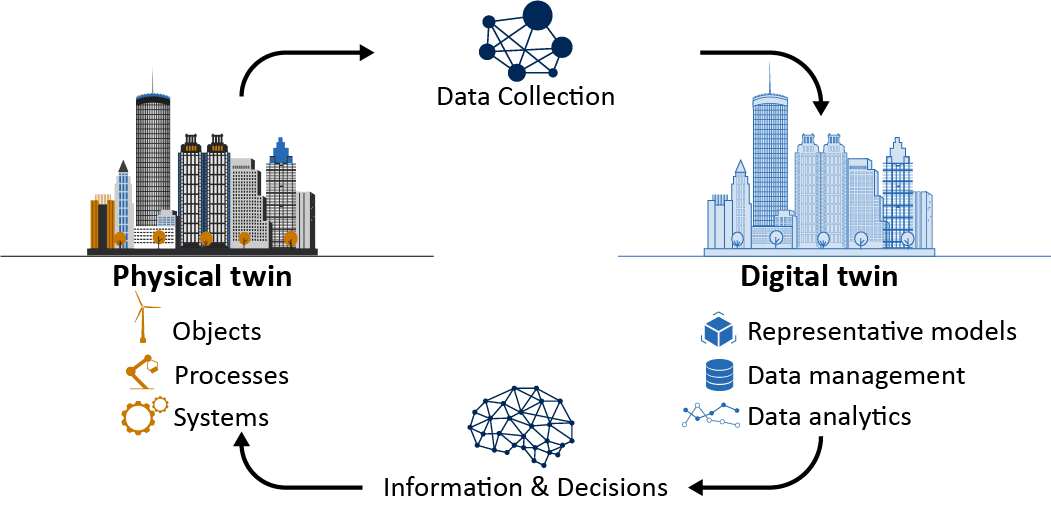

Regardless of what the visual representation of a Digital Twin looks like, the one thing that they all have in common is that they are periodically updated to reflect the actual status of the thing they are twinning. These updates can occur either automatically, via sensors, or via physical inspection of the asset by trained personnel equipped with a spreadsheet.

How Does Digital Twin Technology Work?

Digital Replica of Physical Assets

While Digital Twins of intangible assets such as biological systems or chemical processes don’t require a three dimensional representation, Digital Twins of physical assets such as plant machinery or buildings often do.

But the visual representation is just a small part of the equation. A Digital Twin without a means of communication with the physical counterpart is simply a 3D model.

How do you Design 3D Digital Twins?

How are 3D Digital Twins Captured?

The virtual 3D representation of the physical asset can be captured using various different 3D scanning technologies, such as laser scanners or photogrammetry, or can be constructed using 3D CAD software.

High definition CAD software such a Solidworks, or Catia can be used when there is a need for creating a 3D model with sub-milimeter precision, or when a less detailed model is acceptable, mesh-based 3D modeling software such as Blender can also be used.

The detail represented by the Digital Twin depends on the use case. For example, if an infrastructure operator needs to monitor how rust is forming on a cellphone tower, it may be sufficient to use periodic drone-based photogrammetry to capture the exterior surfaces of the asset in question, as it changes over time.

If a more detailed Digital Twin is required of a complex assembly (such as a jet engine), then it may be preferable to use CAD to model individual components inside the assembly, and assemble and mate the components together inside a virtual environment.

Digital Twin platforms are software applications that enable the creation and management of Digital Twins. These platforms typically include a set of tools and services to support the creation, visualization, and analysis of Digital Twins, and allow the visual components to reflect the gathered sensor data. These platforms often contain predictive algorithms and machine learning capabilities to assist with predicting the future state of the asset.

Some common Digital Twin platforms include Siemens’ MindSphere, PTC’s ThingWorx, Ansys Twin Builder, and IBM’s Watson IoT.

Why Create a Digital Twin from 3D Laser Scanning?

Why Create a Digital Twin from 3D Laser Scanning?

Industrial Applications

Digital Twins are found in any industry where it is needed to gain actionable data from the current state of the asset under observation. They are used extensively in infrastructure and can be found in water neworks, electrical grids, power plants, roads and rail.

In industry, they can be used to monitor individual machines, such as engines, where the Digital Twin can be used to check on the health of the machine as it runs. This digital copy can be used to answer “what-if” scenarios. For example, an operator may wish to know how changing a lubricant in the machine could affect the its operating temperature.

Digital Twins can also monitor entire processes such as a metal stamping production line in a factory. In this example, multiple simulations are connected and can be used to determine the effects of how variations of metal stock thickness affect tool wear, and by extension, machine downtime and throughput.

Not all Digital Twins are used to monitor mechanical equipment. Some Digital Twins can be used to monitor biological and chemical processes, such as those that take place in anaerobic digesters, where an operator can see how varying factors can affect the yield of gases produced.

Real-Time Data

Real-time data is sent to the Digital Twin through various IoT devices such as sensors, cameras, and other measurement sources that are connected to the object or mechanism being replicated. These devices collect and transmit information to the platform through wireless or wired communication networks.

The data is then processed by the platform using machine learning algorithms to update the model in real-time. The platform can also use APIs (Application Programming Interfaces) to collect inputs from other systems or software applications. This allows for a continuous flow of information to the Digital Twin, enabling the platform to provide insights and simulations based on the most up-to-date information available.

Improve Performance & Drive Efficiency

Digital Twins contain a wealth of information that can be used to create actionable intelligence to optimize a product, system or process. Ultimately, these data-driven decisions are designed with one thing in mind – to drive profits and maximize your bottom line.

Real-time sensor feedback can provide up-to-date status on the performance of a system or test processes, and can help narrow down factors that may be impeding performance. Once the source of the bottleneck has been identified, a Digital Twin can be queried on how the deficit can be mitigated and improved.

Many Digital Twin systems contain DoE (Design of Experiments) functionality, and so can populate an experiment model space with real-time data and build a predictive model that can answer these “what if” questions without the need for performing costly real-world experiments.

The results of these simulations can be applied to the real-life counterpart, and can therefore solve problems and increase system or process outputs, which is what efficiency is all about!

Immersive Experiences

A significant benefit of having a 3D Digital Twin is that it is a direct visual replica of the asset being twinned, which makes it very intuitive to understand. This can be especially useful when communicating information to non-technial stakeholders.

Many companies are putting Digital Twins in the metaverse, which not only enhances the collaborative experience between stakeholders, but can become super-immersive when coupled with VR and AR technologies.

Some Digital Twins for example, utilize AR to show assets that may be obscured from view in the real world, such as buried pipes or electric cables on a construction site. This can help with project planning, and can even increase site safety by informing workers where it is safe to excavate.

How Large is a Digital Twin?

Digital Twins come in all shapes, sizes, and levels of complexity. In infrastructure Digital Twins used for urban planning, there are assets that are as small and basic as a street light.

Moving up in scale, there are Digital Twins as large as a whole building, which can be used for facilities management purposes, such as maintaining the comfort of the inhabitants, oroptimizing power consumption based on real-time data gathered by the sensors in the building.

There are even Digital Twins of entire countries, with Singapore having the honor of building the first city-wide Digital Twin. City-sized Digital Twins are used for urban planning, road traffic management, and even optimization of the power grid.

The largest 3D Digital Twins in terms of geographical size, are planet-sized Digital Twins. There are multiple Digital Twins of Earth in development, emulating domains such as climate, ice coverage, and the built environment.

Are You Interested in Having a 3D Digital Twin Model Created for Your Facility?

Call 866-687-7784 or email [email protected] to get started 3D Laser Scanning & Modeling for Digital Twins.