Tank 3D Scanning

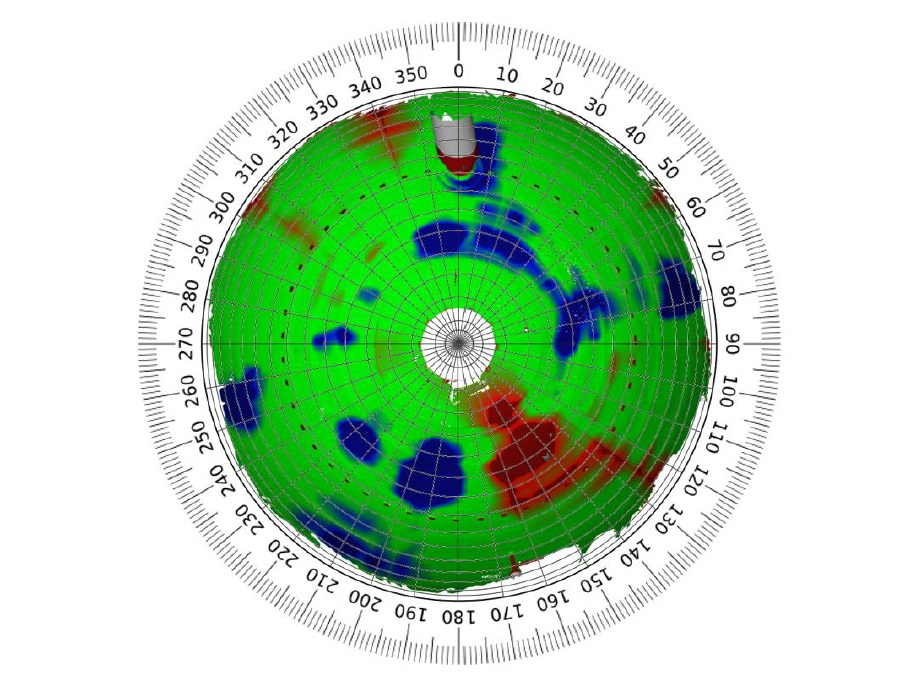

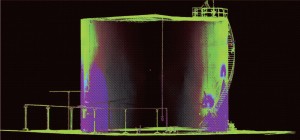

For large storage tanks, 3D laser scanners capture accurate geometry information that can be used to analyze the true shape and any deformation of the tank structures. Older measurement techniques required multiple measurements and a lot of time. 3D scanning of tanks makes this process faster and more accurate millions of measurement points in a single scanning session. .

Advantages of Tank 3D Scanning

3D laser scanners can capture very accurate measurement information in a short period of time. Captured data is then analyzed either in the office or on a mobile computer to provide:

- As-built 3D models of the tank structure, footing and equipment

- Height and diameter measurements

- Angle or tilt information

- Shape information, such as tank roundness

- Area/volume measurements

- Deformation, or change, in objects over time

Many of these measurements from 3D scanners can be used to provide additional information for tank applications, such as:

- Inspection

- Design/modification projects

- Deformation monitoring

- Containment dike analysis

- Volume calibration

For structural design projects or tank modifications, such as replacing a roof or seals, the true shape and condition of the tank can be critical for ensuring that the design fits the existing conditions; hence reducing costly delays or rework. 3D Tank Scanning provides a way to quickly and accurately obtain the existing condition information. While tank thicknesses are effective for the monitoring of structural integrity, positions obtained from 3D laser scanners can be used to complement thickness measurements by analyzing the deformation or movement of the tank over time.

In addition to tank inspection applications, 3D laser scanners can also be used for tank calibration— creation of accurate filling tables. In contrast to traditional methods of strapping or measuring with a total station, the technique involves placing the 3D scanner inside the tank, while out of service, to capture the tank interior. Data for both the tank floor or sump and filling volume are recorded in a single operation, and an estimation of tank thicknesses is not required as the internal cavity is directly measured.

In conclusion, 3D scanning services offer reduced data collection time, less time in the tank interior, reduced labor costs, higher accuracy and more comprehensive data.

Tank 3D Scanning from Arrival 3D will save time and money for your business.

Do you need a tank scanned?

Capture your tank with incredible speed and accuracy and receive a CAD model.