Factory 3D Scanning

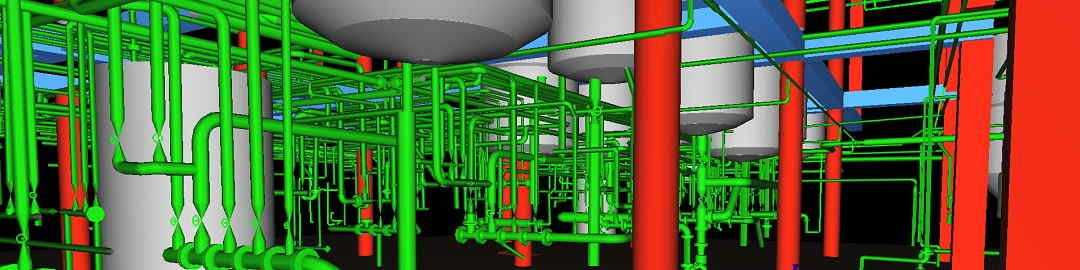

Capture your industrial process piping and equipment in digital 3D

If your job involves creating as-built CAD models of process piping environments, you are in a prime position to heavily benefit from 3D scanning technology. Benefits include:Capture hundreds of pipe segments with a single scan in mere minutes Scan from anywhere using a tripod-mounted scanner Extended reach of up to 1000 ft Scan indoor or outdoor Safe for use around people Zero interruption to your operation

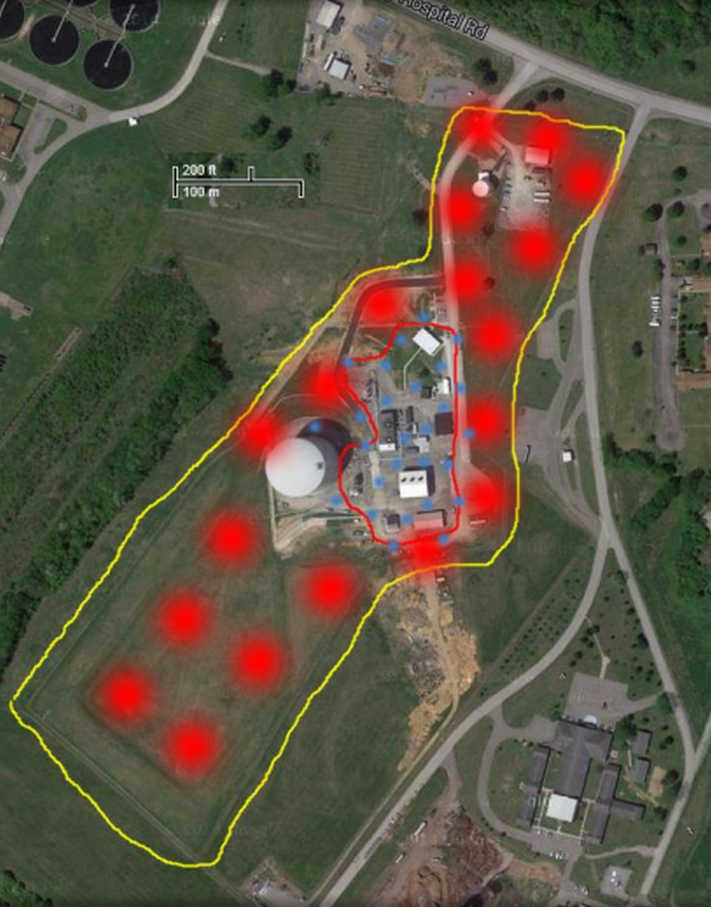

High detail, broad coverage, or all three - it's your choice

Every scan has a plan that is unique to your project. If you are interested in seeing every 1″ conduit that is inside a building, the scan plan will involve closely-spaced scans and more of them in order to capture all of the conduit from every angle. If your area of interest is much larger, such as capturing 12″ piping runs across the property of your facility, the scans will be spaced much farther apart. In either case, we make the best and most efficient use of the on-site scanning time so as to accomplish your needs with minimum cost.

Point Clouds - useful in themselves

New software tools allow you to utilize point clouds directly and easily. Point clouds are the raw data that is collected from the scanner. In the past, expensive and/or cumbersome software was needed to work with point clouds. But now, there are many things you can do with just the raw scan data, making 3D scanning an incredible value. These things include:View the scans as full-color panoramic images Take measurements Create ortho-images Create color images and fly-through videos Perform clash detection Walk through the site virtually

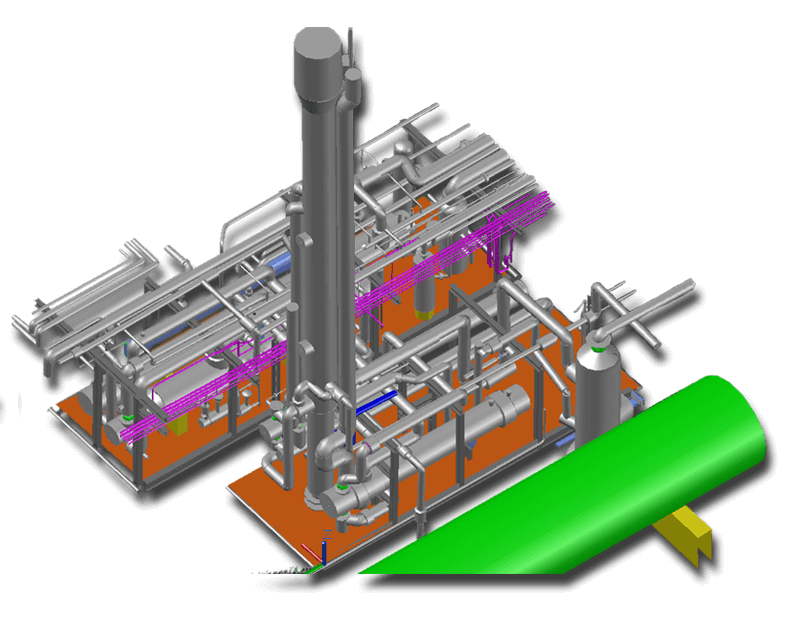

Convert point clouds to CAD models

If you need an as-built CAD model of your process piping and equipment, save time and increase accuracy by utilizing our 3D scanning services. With an accurate as-built CAD model, your engineers can route new piping and equipment around existing structures. More precise engineering means less problems during construction, saving you from costly delays and change orders.

World class 3D scanning services

Capture your facility with incredible speed and accuracy and receive a CAD model.