Power Plant 3D Scanning

3D Scanning for your power plant project

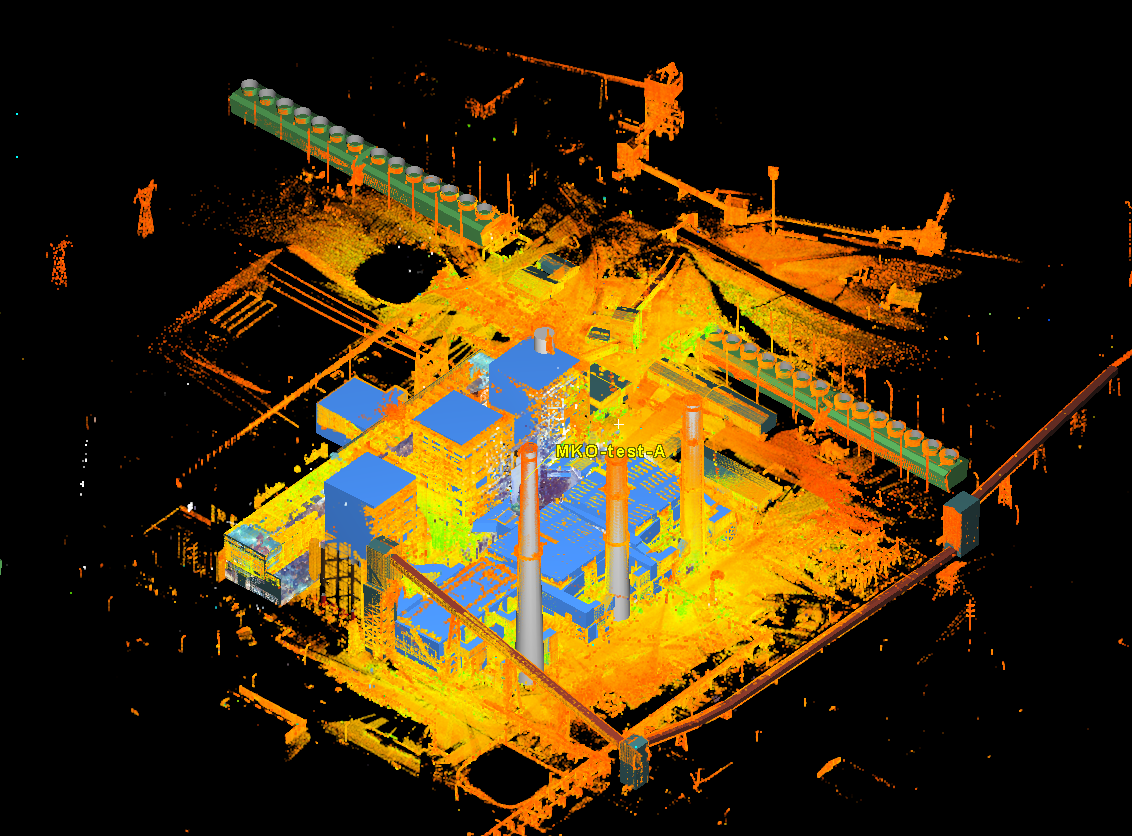

3D scanning a power plant is the type of thing we do best. The size and complexity of a power plant requires high speed scanning equipment with long range and high accuracy. 3D laser scanning technology brings many benefits to power plant engineers. Using a digital 3D scan for as-built information, engineers can design complicated retrofits and upgrades that fit the first time upon installation, avoiding costly and usually inevitable engineering errors or miscalculations. 3D scanning makes design work easier and allows engineers to work in a highly efficient manner. It positions power companies to be prepared for the future, when 3D engineering is the standard. You won’t be left behind when your competitors embrace 3D engineering, in fact you’ll be far ahead.

3d laser scanners pay attention to detail

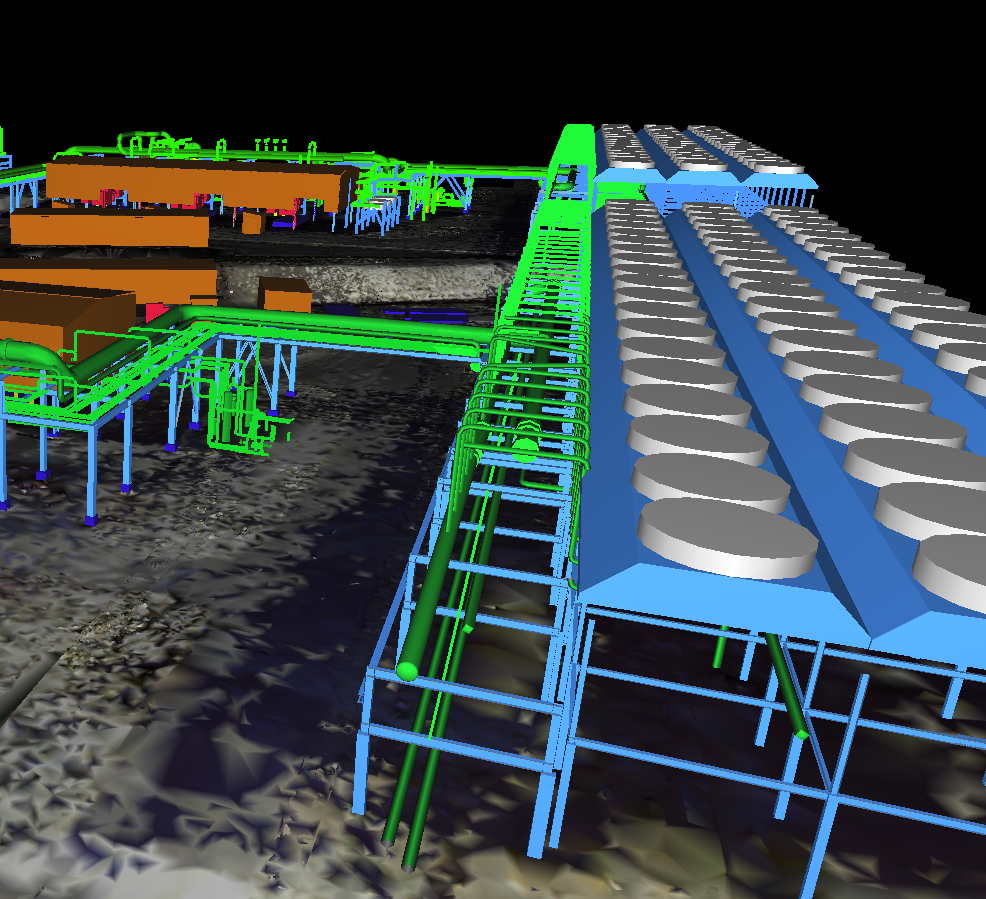

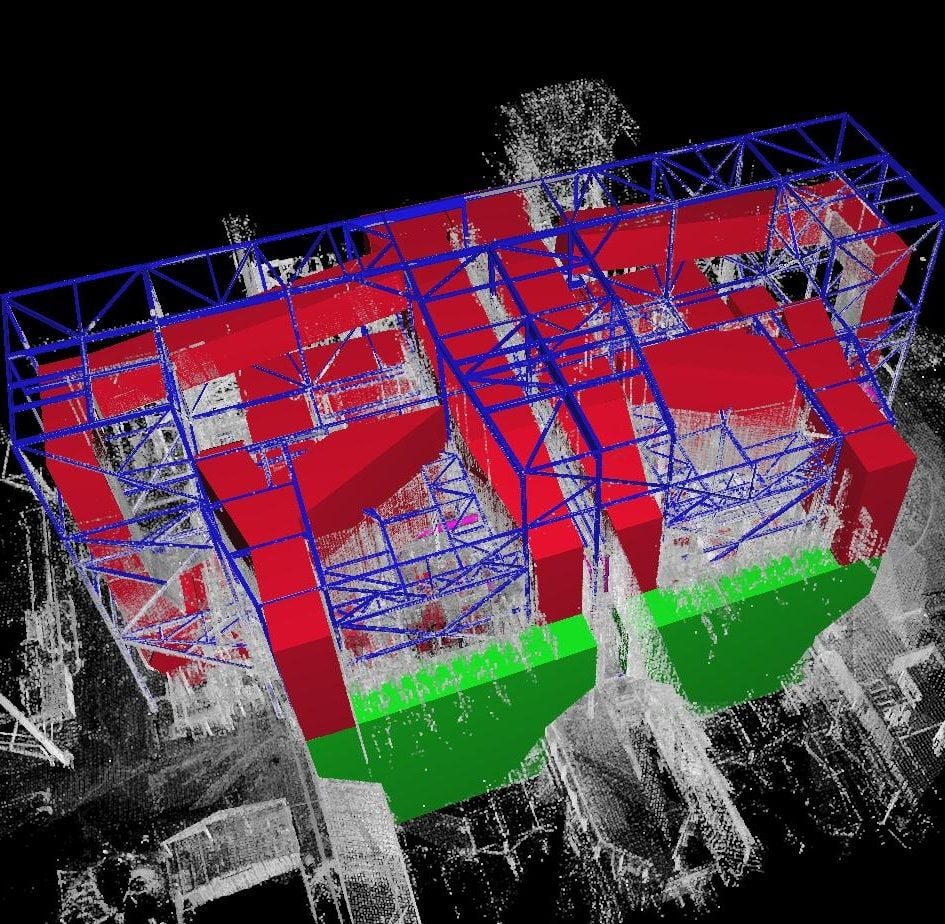

3D scanning has the ability to accurately capture everything that is seen in any particular location, including structural steel, ducting, and even small stuff like lights, handrails and bolt patterns. It provide engineers a digital twin to refer to. Within this digital plant they can look around, take measurements, and create 3D models and 2D drawings that can be used to support specific projects. The resulting CAD drawings and models created from 3D scans will lead to successful projects that are based on current information and have minimal clashes interferences and other installation problems that we all want to avoid.

What are the steps for power plant 3D scanning?

1. Identify the scanning scope area

2. Capture a series of scans

3. Merge the scans

4. Align the scans with plant coordinates

5. Produce a 3D cad model or other desired deliverable.

what does power plant 3D scanning cost?

Every power plant project is different, but we can tell you that the typical budgetary range for this type of scanning is in the tens of thousands of dollars. Contact us and we’ll be glad to provide a precise and competitive quote.

what is the process like?

3D laser scanning works by capturing a 360-degree sweep of all nearby of equipment in a single scan. By merging multiple scans, sections of the plant may be captured in a single day. Highly congested areas can be scanned in this manner. 3D scanners are capable of taking measurements accurate to 1/4” from a distance of 100 meters or more, resulting in accurate as-built data. The ability to capture measurements from a distance can increase safety and reduce scaffolding expenses. The resulting 3d scans provide a wealth of data from which can be extracted CAD model, panoramic imagery, ortho-images and other useful aids to your projects.