CASE STUDY: 3D Scan Mine Conveyor Belt in Reno, NV.

Arrival 3D are tasked with the 3D Scanning of this industrial mine conveyor belt for the purposes of “As built” documentation to facilitate changes & additions.

Arrival 3D are tasked with the 3D Scanning of this industrial mine conveyor belt for the purposes of “As built” documentation to facilitate changes & additions.

3D Laser Scanning in Reno, NV: Our client, an international mining company, have plans to add equipment to this existing industrial conveyor belt. The starting point is to document the existing structure via 3D Scan Data, which is where Arrival 3D bring value.

The resulting Scan Data, a “point cloud” comprising millions of points of data, can be utilized as is for both measurement and spacial planning, or the data can form the basis of an accurate, geometric CAD model. Arrival 3D routinely provide to clients both point cloud, and Revit CAD models.

Our client required thorough scanning of this equipment from multiple heights at the sides, from above and the underside where access permits. The compact size and versatility of our Leica RTC360 enabled our scan technicians to capture the structure in its entirety. The Arrival 3D data collection process takes only a few hours onsite and we require only easy access to the scanning subject.

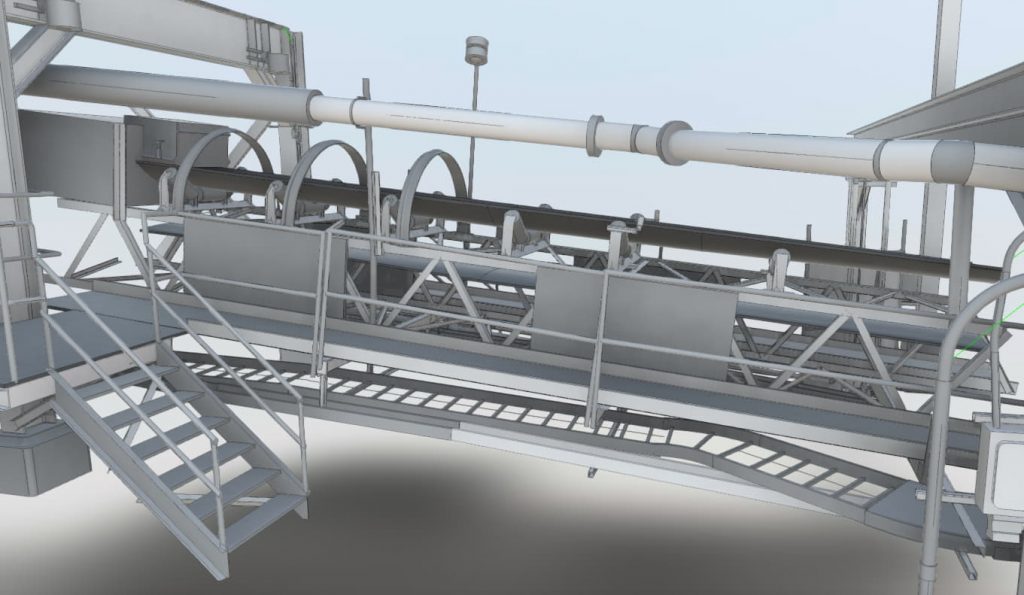

An image of the mine conveyor belt to be 3D Laser Scanned. Note the Arrival 3D Leica RTC360 in one of its multiple scanning positions.

Reno, NV.

An Arrival 3D Leica RTC360, seen here 3D Laser Scanning the conveyor belt in one of multiple scanning locations.

Arrival 3D have a large inventory of 3D Scanners suited to a variety of tasks. Our most recent acquisitions, and currently our favored multi-tasking 3D Scanners, are our Leica RTC360’s. Arrival 3D now have several Leica RTC-360’s positioned strategically around the United States. We use the RTC360’s frequently due to their great versatility; portable size, long range accuracy and rapid scanning capability.

3D Laser Scanning an Industrial Conveyor Belt in Reno, NV.

Our client chose, in this case, to receive a fully detailed Solidworks CAD model as well as the unified Point Cloud. The CAD model will serve as the basis from which to integrate the new equipment into the existing structure.

Above, the 3D Laser Scanned full-color Point Cloud of the Conveyor Belt pictured top.

Arrival 3D have in the past been called upon to scan architectural projects where the client had attempted, unsuccessfully, to take manual measurements of the area they have intended to change. Later, having spent a great deal of time & money, and having constructed sub-assemblies that won’t fit, Arrival 3D have been called upon to 3D Scan and document the areas in question. Rarely do existing architectural structures have existing, or accurate, blueprints. Furthermore, existing structures can subtly change dimensionally over time from their built condition, for countless reasons.

Arrival 3D are equipped and able to rapidly document existing conditions, provide that data to our clients in a multitude of formats, and ultimately save our clients time, trouble and valuable funding in documenting the reality of projects presented to us. The peace of mind that is inherent with a digital representation of a project is priceless and the ability to share this accurate data with the entire team instantly, and often remotely, is one of the wonderful benefits that these technologies allow us today.

Above, a view from the point cloud of the industrial mine conveyor belt.

The Arrival 3D Solidworks CAD model developed from the registered Point Cloud.