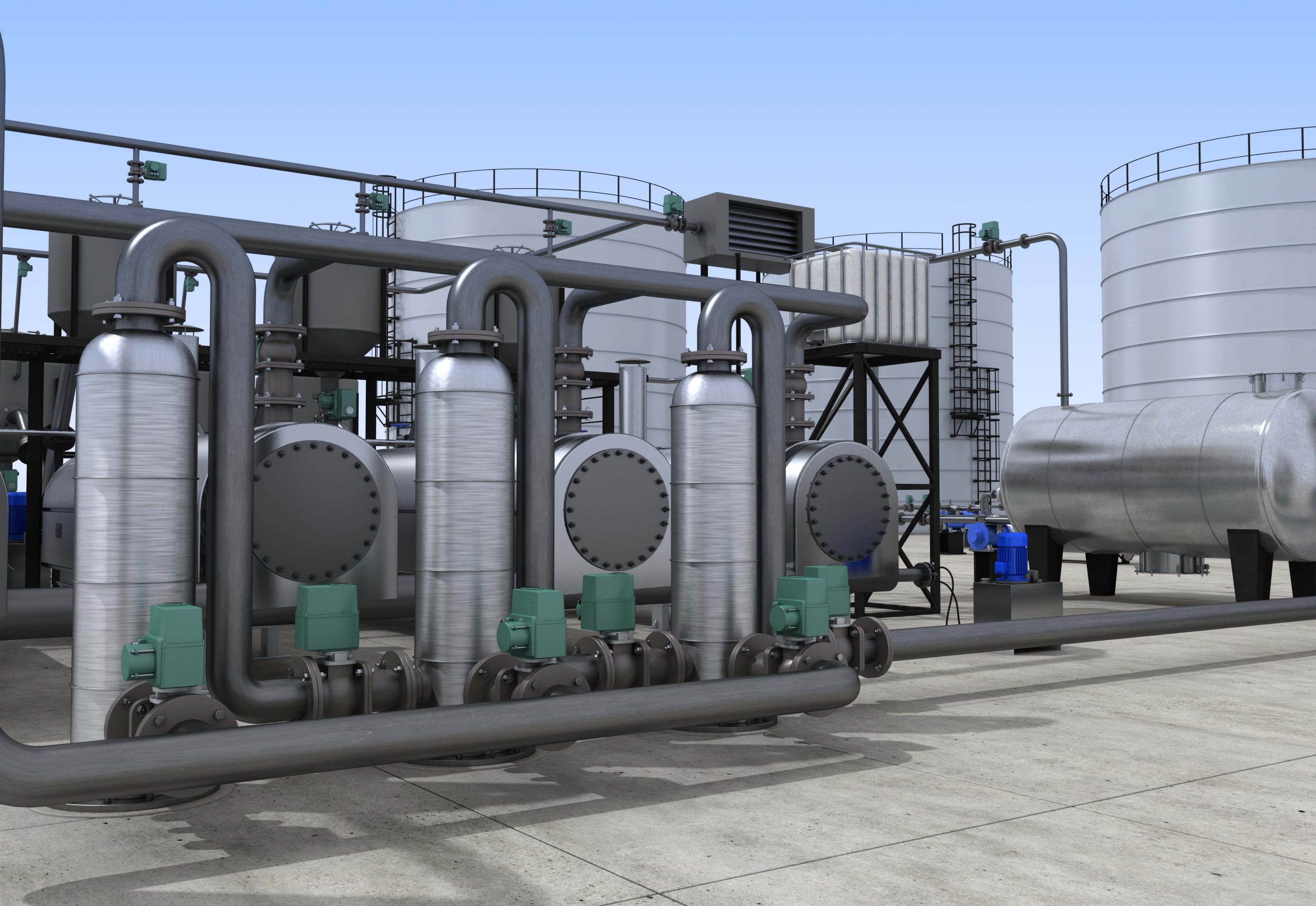

CASE STUDY: Scanning an Industrial Plant in the Central Coast, CA.

Heavy industrial environments are always changing, like this one we scanned near San Luis Obispo, CA. With capital projects, the stakes are high and it has to be done right. That is why this company trusted Arrival 3D to capture as-built information of their plant for engineering and planning purposes.