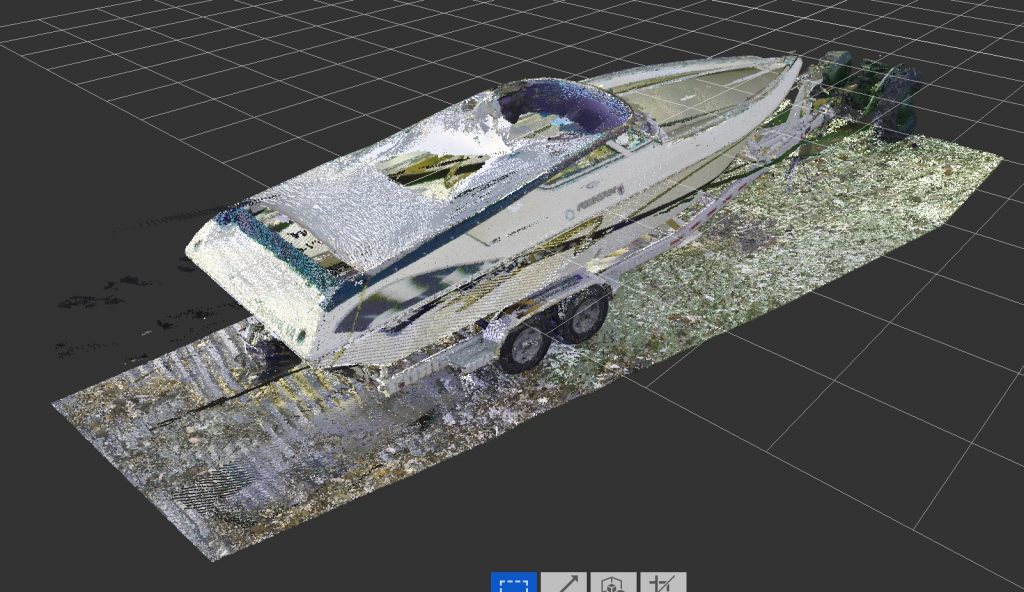

Laser scan 29' boat and trailer

This beautiful boat received an upgrade, a brand new trailer. And not just any trailer — a custom-built fully welded and perfectly fit one with waterproof hubs. How was this accomplished? Using 3D laser scanning technology.

Get A Free Quote

Project overview

The primary aim was to perform a complete 3D scan of the 29′ sport boat located near Norfolk, VA. The focus was on capturing the outer hull and underside of the boat up to the waterline. The project also required the scanning of the boat’s trailer and incidental capture of other boat parts.

Methodology

- Pre-Scanning Preparation: Because the boat was positioned on a trailer, it was necessary to move the trailer to open, flat ground with at least 5 feet around it. This helped ensure complete coverage of the hull and relevant areas.

- 3D Scanning Technology and Process: A State-of-the-art Leica RTC360 scanner was utilized to capture high-precision data points of the boat’s hull and supporting trailer structures. Scans of varying height and position were strategically executed to cover the hull comprehensively. Because we needed to scan the boat in place in it’s trailer, we utilized a tripod capable of laying flat in order to slide it under the trailer in low-clearance locations. This saved the customer the hassle and expense of needing to lift the boat off the trailer and place it on a dry dock stand.

- Photographic Documentation: Alongside the 3D scanning, the technician also took high-resolution photos of the boat’s underside using a smartphone camera. This provided additional visual documentation to complement the 3D data.

data processing and analysis

- 3D Laser Scanning Processing and Registration: Post-scanning, the collected data points were processed with Leica Register360 software to form a unified point cloud. This involves careful checking of the alignment to ensure the point cloud is free of “doubling”, a type of error that can occur with any laser scan. We also remove un-needed scan data such as that of the surrounding buildings/environment and ground.

- Point Cloud Export: The finalized point cloud was exported in PTS format with points equally spaced at 2mm, a generic format compatible with MYCO’s requirements. This format ensuring ease of use with surfacing software such as Geomagic, which this customer uses. 3D

Deliverables

- Point Cloud and Photographic Data: Arrival 3D delivered the comprehensive point cloud file in PTS format along with the photographic documentation of the boat’s underside. These were provided through a secure download link.

- Alignment Specifications: The point cloud was aligned in an assumed coordinate system, squared up and upright for ease of interpretation. However, any specific alignment needs or changes post-scan completion would be addressed with potential additional charges.

schedule and execution

- Field Work Duration: The scanning process was efficiently completed in a couple of hours, demonstrating the high speed capture capability of 3d laser scanning service technology.

- Post-Scanning Timeline: After the fieldwork, business days was required for the registration process and final file delivery. This timeline ensured thorough processing and quality assurance of the data.

Conclusion

Mass-produced, on-size-fits-all trailers work for some things, but there are special boats that call for a custom trailer, a trailer that fits like a glove and is built to near military specs. Constructing a trailer like this requires high precision, such as that achieved with 3D laser scanning services. This case study explains the process of such a project, and how it can make a difference with how things are made. If you have a need for 3D laser scanning services, please contact us and tell us more about your project!