CASE STUDY: 3D Scan Wind Turbine in Tehachapi, CA.

Arrival 3D are tasked with the 3D Scanning of this large Wind Turbine to analyze it’s condition relative to its Factory Specification.

Arrival 3D are tasked with the 3D Scanning of this large Wind Turbine to analyze it’s condition relative to its Factory Specification.

3D Laser Scanning in Tehachapi, CA: Our client, a leader in renewable energy, requires 3D Laser Scanning of a wind turbine to assess its condition relative to factory specifications. Arrival 3D have carried out several of these projects in recent years and have a library of CAD model Wind Turbines created to exact factory specification. It is straightforward for us then to 3D Laser Scan turbines in the field and to create analysis reports detailing any deviations from factory specification.

The Arrival 3D data collection process takes only a few hours onsite, the equipment is compact and clean, and we require only easy access to the property.

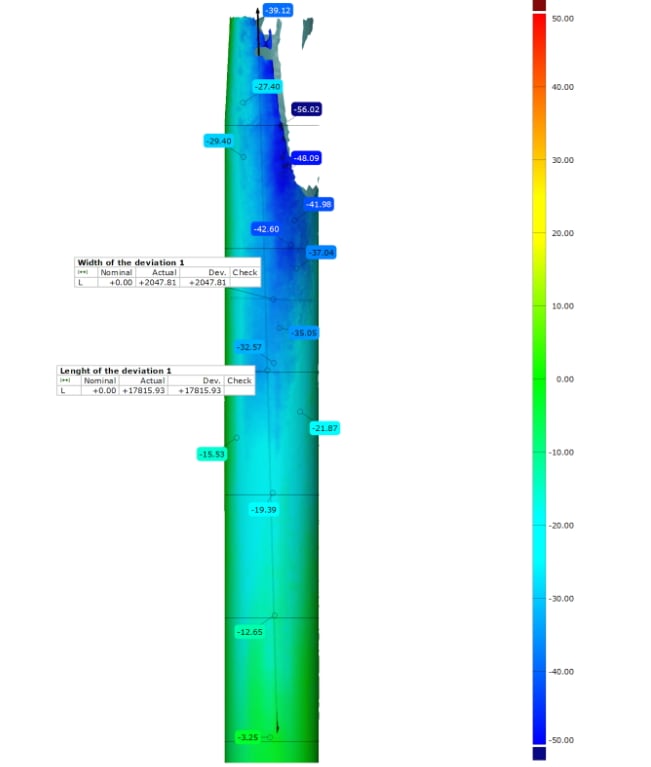

In the image to the right, it can be seen that there is a creased dent in the upper section of the tower. The processed scan data offers the ability to assess the degree of this damage in comparison to the factory specification.

An Arrival 3D Leica C10 long range scanner, in one of multiple positions scanning a wind turbine in Tehachapi, CA.

Tehachapi, CA.

An Arrival 3D Leice C10 scanner in one of multiple positions during the scanning of a wind turbine. Clearly, this particular turbine is not in perfect operating condition!

Arrival 3D have a large inventory of 3D Scanners suited to a variety of tasks. For the purpose of scanning tall wind turbines we utilize a Leica C10 long range time-of-flight scanner.

3D Laser Scanning a Wind Turbine in Tehachapi, CA.

Our client chose, in this case, to receive a complete Scan to CAD analysis report of this wind turbine.

This report is generated by comparing our newly acquired Point Cloud to our existing database of Wind Turbine models. If the model of turbine is in our database we can efficiently compare the scan data to the factory specification and generate a report indicating areas of deviation. This information is illustrated both graphically and dimensionally. When we’re asked to scan a turbine of a design we’re not already in possession of, we source the data necessary to model it in CAD and add it to our growing database.

3D Laser Scanning facilitates the creation of highly accurate CAD Analysis Reports, a service that Arrival 3D routinely provide to our clients.

Arrival 3D have in the past been called upon to scan architectural projects where the client had attempted, unsuccessfully, to take manual measurements of the area they have intended to change. Later, having spent a great deal of time & money, and having constructed sub-assemblies that won’t fit, Arrival 3D have been called upon to 3D Scan and document the areas in question. Rarely do existing architectural structures have existing, or accurate, blueprints. Furthermore, existing structures can subtly change dimensionally over time from their built condition, for countless reasons.

Arrival 3D are equipped and able to rapidly document existing conditions, provide that data to our clients in a multitude of formats, and ultimately save our clients time, trouble and valuable funding in documenting the reality of projects presented to us. The peace of mind that is inherent with a digital representation of a project is priceless and the ability to share this accurate data with the entire team instantly, and often remotely, is one of the wonderful benefits that these technologies allow us today.

Scan to CAD analysis.

Scan to CAD analysis.