Industrial CT Scanning

What is Industrial CT Scanning?

Part scanned using industrial computed tomography

How Does an Industrial CT Scan Work?

How Accurate is Industrial CT Scanning?

when average 3D scan quALITY is not good enough

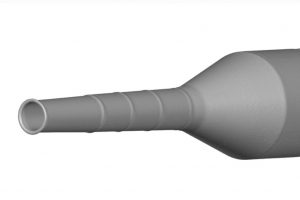

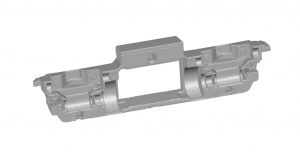

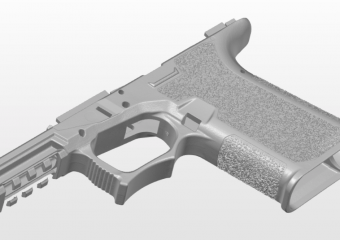

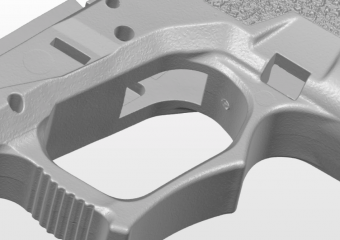

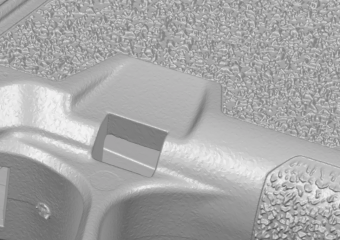

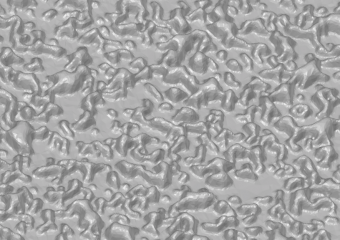

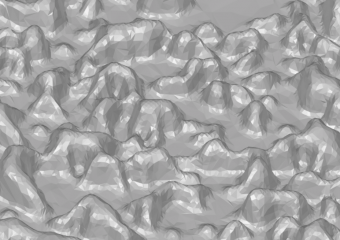

Take a look at this firearm part that we scanned using CT scanning. At first glance you may think it resembles a scan taken by your run-of-the-mill scanner. But zoom in further, and you see that it is no ordinary scan. What looks like some fine texture at first glance looks like a mountain range up close.

Not only is the scan of exceptionally high resolution, it is also extremely accurate, so that the scan may be used as a reliable reference for designing add-ons, changes, accessories etc. We can support your project with this same level of detail and accuracy using industrial CT scanning services.

What is the Difference Between Medical CT and Industrial CT?

While both medical and industrial CT scans employ the same underlying technology — capturing multiple two-dimensional X-ray images and assembling them into a three-dimensional model — each serves a distinct purpose and has unique characteristics. Medical CT scanning is primarily designed for diagnosing and monitoring disease within the human body. It focuses on soft tissue contrast and prioritizes patient safety, limiting the radiation dose exposure significantly.

On the other hand, industrial CT scanning is engineered for inspecting a wide range of materials, from plastic to metals. Its emphasis lies in spatial resolution and accuracy, allowing for the detection of minute defects and measurements in objects. Unlike medical CT, industrial scanners can use higher radiation levels because there are no biological safety considerations. Thus, while similar in their operating principle, the primary differences between medical and industrial CT scanning reside in their objectives, radiation dose, and the nature of the materials scanned.

What are the Industrial Applications of Computed Tomography Scanning?

Quality Control and Inspection

Failure Analysis

Assembly Verification

Metrology

Research and Development

Material Analysis

Reverse Engineering

Preservation and Analysis of Cultural Artifacts

Analysis in Geology and Petroleum Industry

Food and Agriculture

More Information About Industrial CT Scanning Services

Are There Size Limitations for Scanned Objects?

Can Any Material be Scanned Using Industrial Computed Tomography?

Can You Scan Multiple Parts at Once?

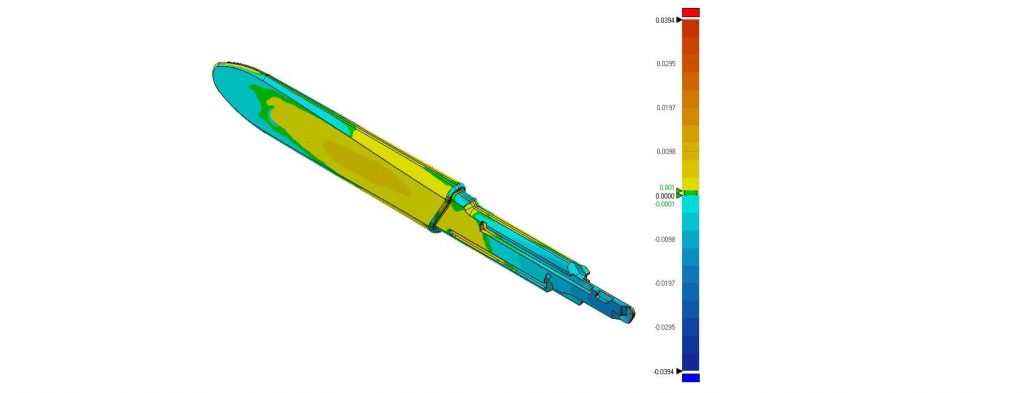

Correlating Colors to Errors

Benefits of Industrial CT Scanning

- High accuracy (to 0.0005 inches or better)

- High speed

- Comprehensive raw data set

- Ability to view internal structures not visible with other technology or non-destructive testing

- Detailed inspection, materials, and failure analysis

- Ease of CAD model creation and output file creation for 3d printing

- Value when comparing scan cost to the depth of analysis and diversity of applications

Examples of STL Files Created Using Industrial CT Scanning Technology