3D Scanning Case Study

inspection of pressure vessel door

Our power generation customer uses pressure vessels in various applications. A tragic accident highlighted the critical importance to them in ensuring that each vessel meets all the appropriate boiler pressure vessel codes. Because vessels tend to expand and contract under different operating conditions, proper clearance is extremely critical in ensuring doors are sealed appropriately to prevent leakages of either high pressure steam or chemicals. In a nutshell, having tight tolerances is crucial to equipment reliability but more so in ensuring it doesn’t compromise safety requirements. To ascertain tight tolerances can be achieved, our customer utilized our 3D laser scanning services which ensured that the contour of the door was maintained with appropriate dimensions which ensured that a tight fitting door was achieved to prevent leakages.

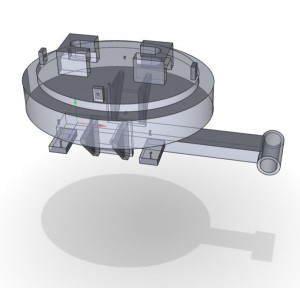

Above: Solidworks parametric model created from scan data

3D scanning was also used to reduced misalignment and compensate for distortion that exists on vessels that have been in service for many years. The scanning data was used to design new doors with tighter seal dimensions to eliminate gaps between the manway and the door. 3D scanning made it possible for them to ensure door is built within tolerance for tighter fit. Tighter tolerances prevent gasket migration. Due to the unfortunate incident, they decided to looked at fleet-wide vessels and found other pressure vessel doors that raised questions about being operated safely without any incidences. Our customer feels that 3D scanning is a valid and affordable way to engineer manway doors.

Read More 3D Scanning Case Studies

3D scanning and 3D printing services

3D technology can simplify your work, save you money, and solve problems in innovative ways.

Our team of experts is made up of engineers, technicians, and CAD modelers. Together we have over 100 years of experience to get your project done right.

We offer high-end 3D scanning services at competitive rates and we pride ourselves on our quick turnaround.