get CAD models for Manufacturing

3D scanning services make it easy to obtain CAD models and drawings for manufacturing even when no drawings exist. All that is needed is a sample part to scan, and the part can be reproduced. The process of Reverse Engineering enables the creation of a part that is better than the original. The part can also be modified per your instructions to create variations and improvements upon the original design. Depending on the manufacturing method, there are things to consider when creating the 3D model to make sure they are optimized for manufacturing.

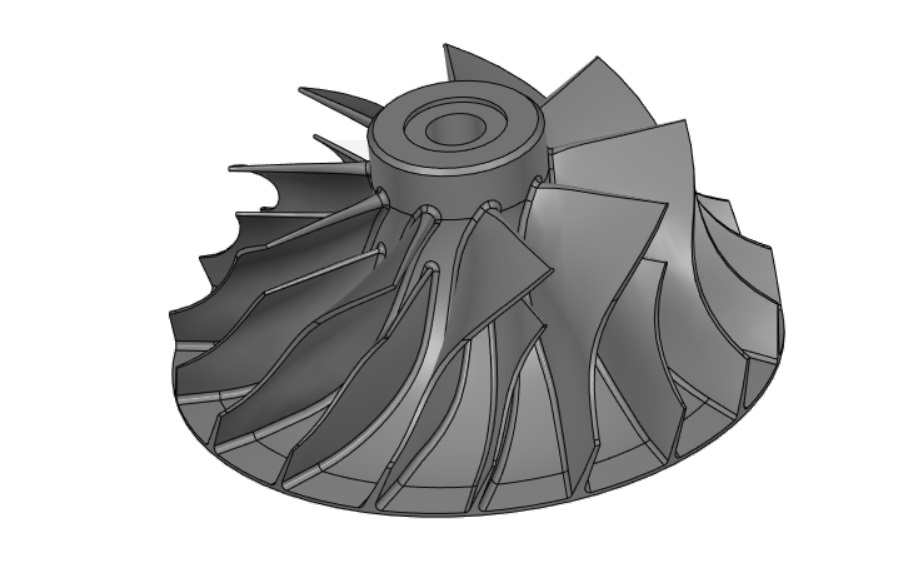

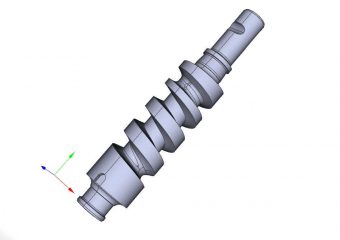

Machined Parts

High quality Class-A solid models can be obtained from 3D scans that are optimized for machining operations such as mills, lathes and CNC routers. Typically, CAD/CAM software is able to use STP and/or IGES files for creating the toolpaths. High quality models ensure that the toolpaths are smooth and uninterrupted. Features like threads and lettering can be included or excluded based on your instructions.

Cast Parts

Flaws in a sample casting being scanned can be removed in the newly-created CAD model. Roughness can also be ignored and modeled as smooth. A scale factor can be applied to account for shrinkage. Mold cavities can be obtained from the reverse of the model, and models can be split into mold halves along a parting line.

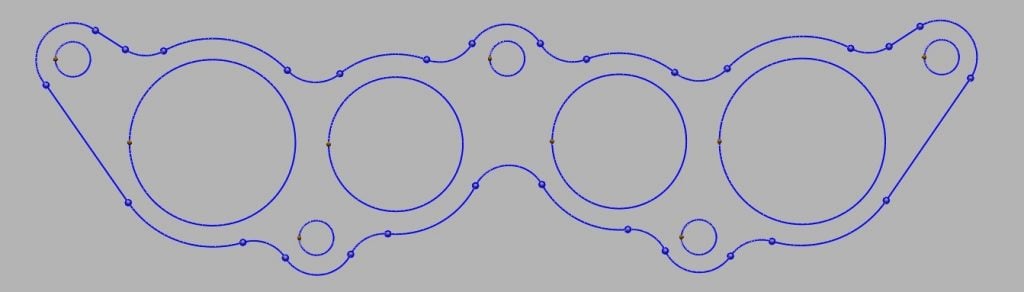

Waterjet, laser cutter or plasma cutter CNC machines

You can obtain 2D curves for machining operations such as waterjet cutting and laser cutting in DXF or DWG format.

injection Molding and other plastic molding types

Even highly intricate and complex parts can be scanned and converted into digital 3D CAD models.

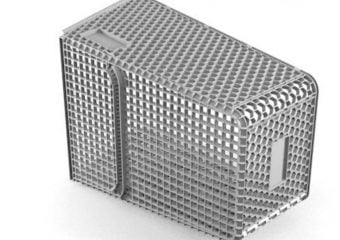

3D Printing and rapid manufacturing

You can get models optimized for 3D printing. These can be directly from the scanner or exported from a CAD program. 3D-print files are usually in STL format and are compatible with all 3D printers. They will be “watertight” (no holes) and be free from surface errors.

If you need to have a part scanned for manufacturing purposes, call us at 866-687-7784, email us at [email protected], or fill out the following form to get started.

[contact-form-7 id="2000" title="Popup Contact Form" html_class="use-floating-validation-tip"]

World class 3D scanning services

Capture your part with incredible accuracy and receive a CAD model.