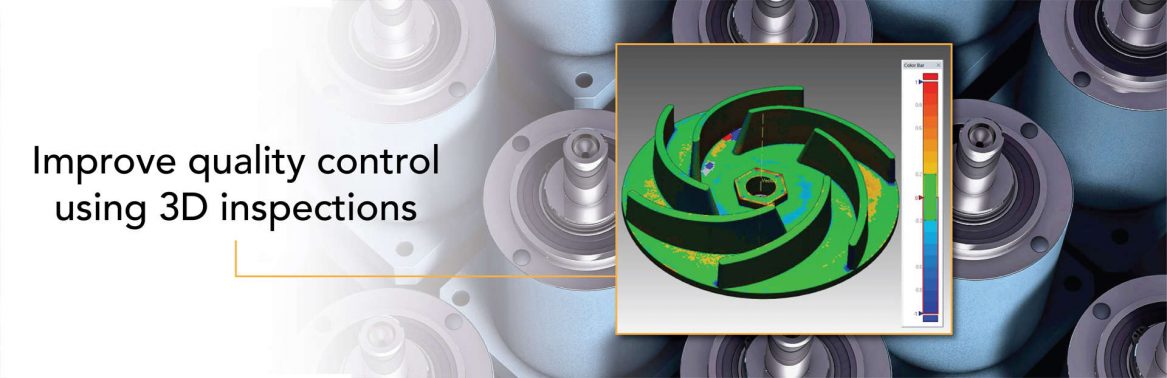

Verify your parts using 3D inspection services

Our 3D inspection services can assist you with quality control in manufacturing, assuring that your parts meet the required specifications before reaching the customer. We can provide a variety of inspection types based on how a part will be used. Depending on the nature of your part, we may utilize a 3D scanner or a touch probe to inspect the dimensions of your part.

Inspection - What is it?

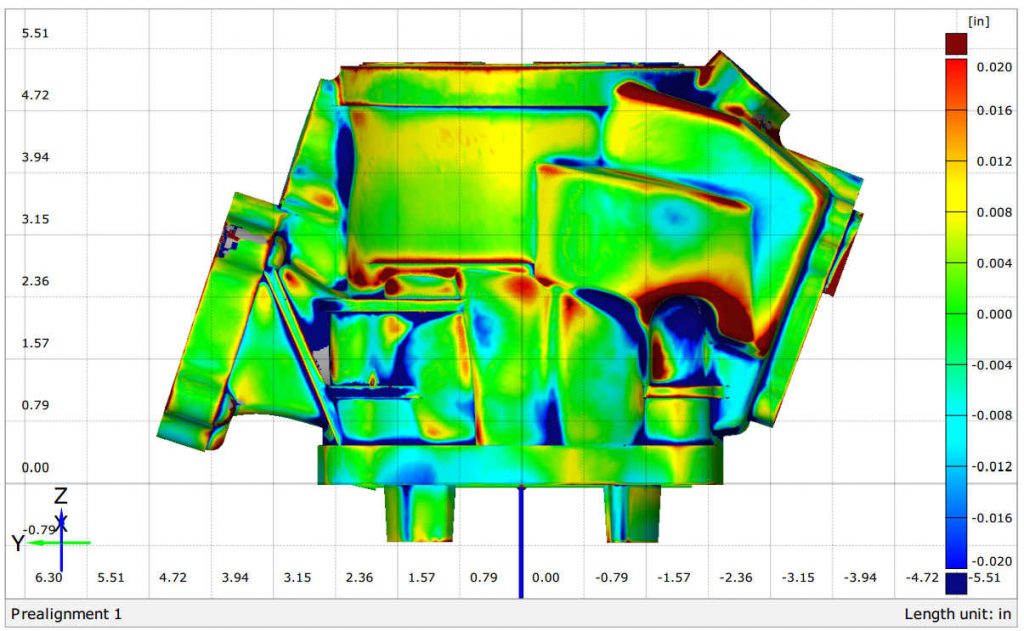

Inspection is a comparison of a set of ideal or required measurements (reference data) to a corresponding set of measurements from the part to be inspected (test data).

The reference data may come in the form of a table, with values at specific points or features, a cad model, or 3d scan. 3D inspection services may require datum measurements, where the part to be inspected is located in a fixture that is specifically designed to orient the part by an ordered method. In some cases, the part may have features that are designed specifically to be referenced by datums, if no functional feature of the part provides a clear reference.

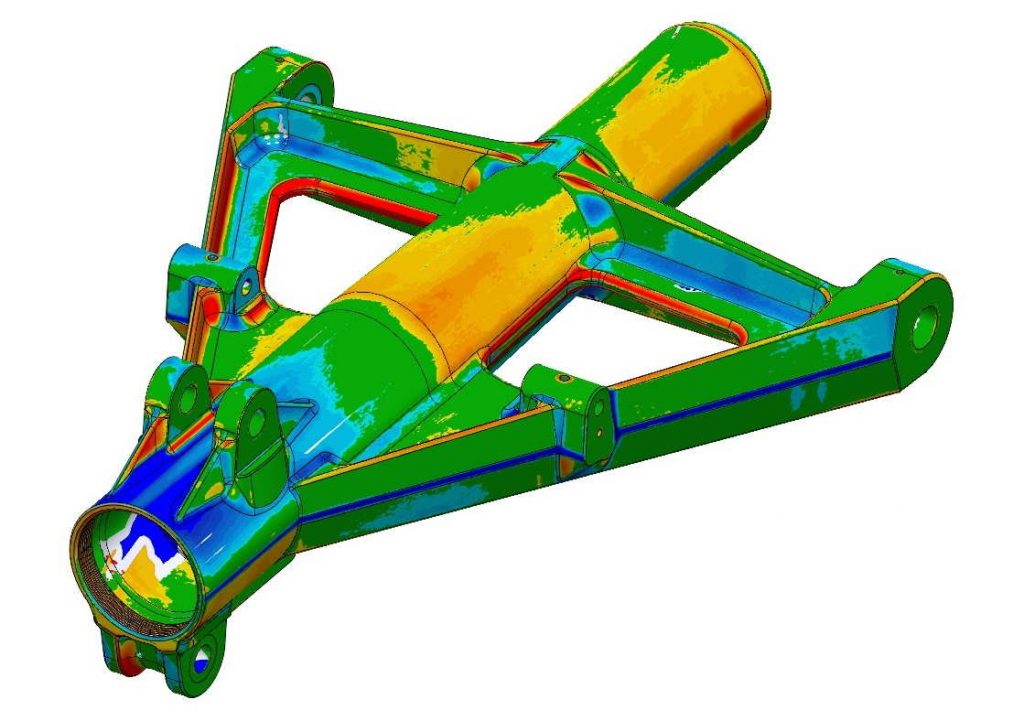

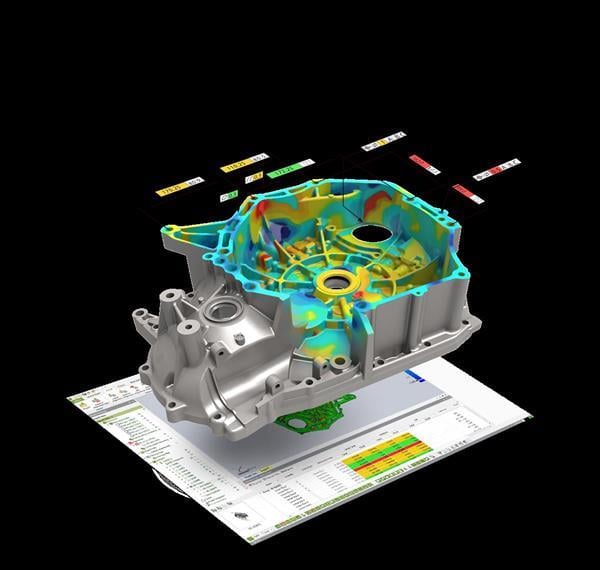

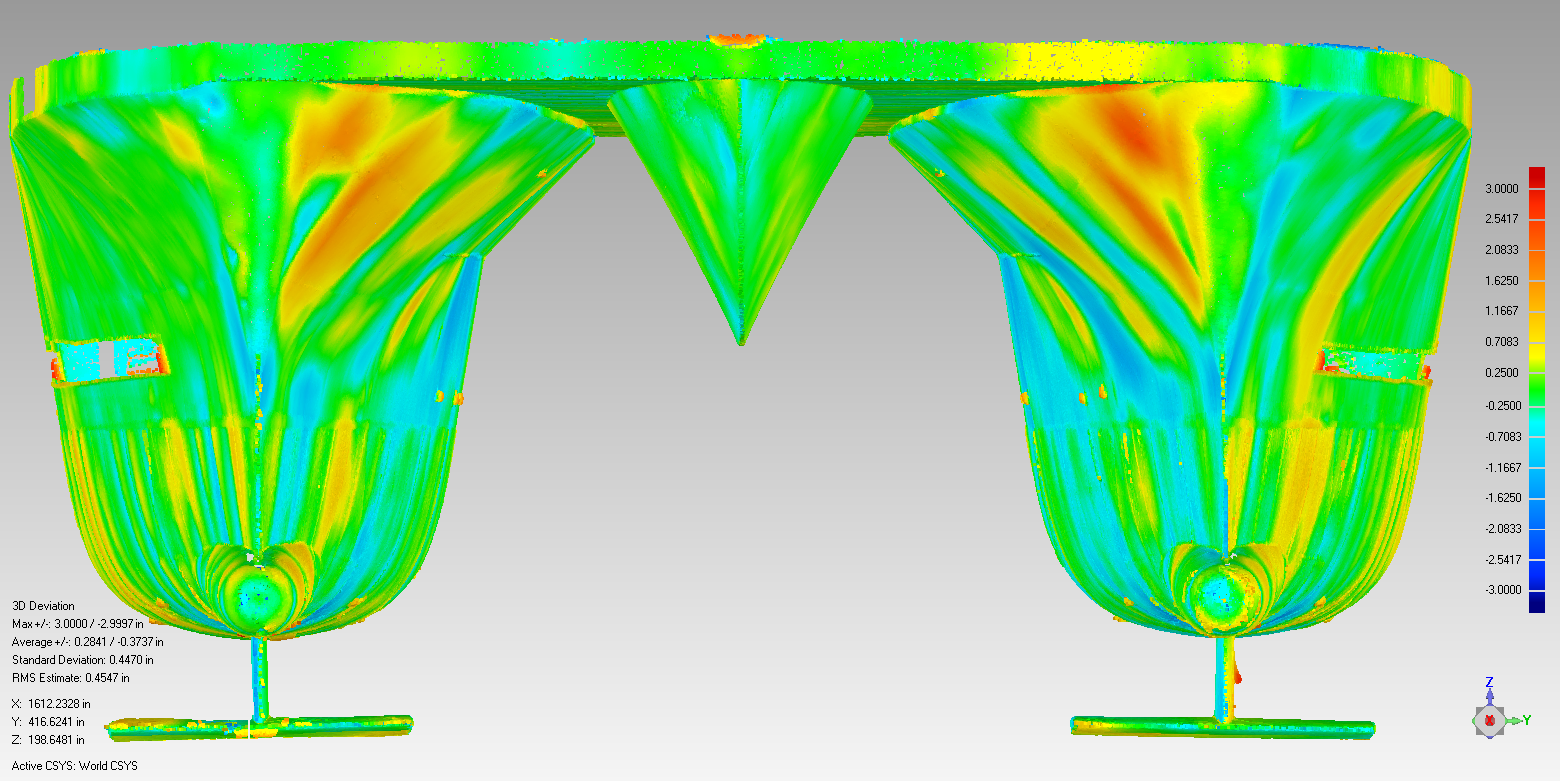

The CMM arm with a laser scanner or touch probe is used to accurately capture the geometry of the part to be inspected. Inspection software is then used to generate measurements from corresponding points or features, or for an entire surface. The results can be in tabular form or a deviation image, depending on the requirement.

How accurate are our 3D inspection services?

We are able to obtain accuracy ranging from .0005″ to 1/8″, depending on the scanning technology used. Typical accuracy for desktop-sized parts is in the rage of .002-.003″. Each part has its own accuracy requirement, which is often the determining factory when deciding which 3D technology to utilize. The inspection technology must provide accuracy equal to or greater than the smallest expected or meaningful difference.

What types of results can you receive?

We can deliver the 3D inspection results in a variety of forms:

World class 3D inspection services

Capture your part with a precise scan and receive informative inspection reports.