The Largest Industrial Metal 3D Printing Services: Brought to you by Sciaky

Designing and realizing large scale industrial 3D metal printers isn´t at all easy as they need to reform a considerable amount of material in a reasonable amount of time for their investment to be worthwhile. This is part of the reason why small scale 3D printers are much more abundant, such as those that are used for small jewelry businesses which are well taken care of with smaller build volumes around 5 x 5 x 7 inches. However, if you want to make to scale car or plane parts it becomes a whole other ballgame. And it is because of this kind of demand in these areas that some companies are stepping up to the plate and delivering the biggest 3D printers on the planet to companies that need them to streamline their productivity.

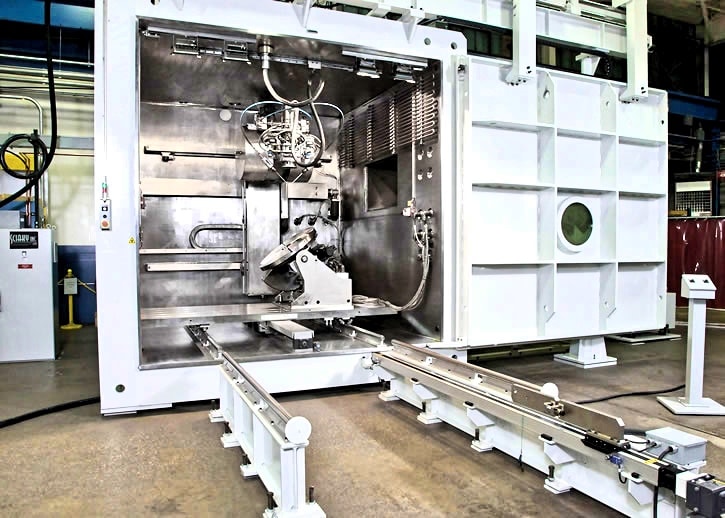

Industrial Metal 3D Printing Services: EBAM 300 Series Pro Metal 3D Printer

Case in point, Sciaky´s EBAM 300 Series Pro boasts an impressive maximum work envelope, or build volume, at a whopping 240 x 55 x 54 inches, putting most other 3D metal printers to shame. It stands alone as the only 3D printer that´s commercially available, of any metal material, by offering construction exceeding 10 feet in length. This technology really means business and it´s quite a sight to see its chamber, which takes up 300 x 132 x 108 inches, in action. It almost looks like it belongs in a spaceship, ironically as it has aerospace implications.

It really is state-of-the-art and to believe this you need not look further than the long list of heavy duty metals and alloys that it can handle and turn into complex machine parts and prototypical realities unlike ever before. These include niobium, inconel, tantalum and even titanium, the toughest of them all and is well known for being particularly difficult to shape. Metals such as these would otherwise, through traditional methods, take months to forge into workable parts, but the EBAM 300 has been able to produce a titanium 10 foot aircraft structure in a turn around time of just 2 days.

It´s able to melt these metals so efficiently thanks to its electron beam which generates a very high level of energy and consequently an astoundingly high degree of control. For this reason its name EBAM stands for Electron Beam Additive Manufacturing and utilizes a patented IRISS closed-loop control system that ensures precision on an absolutely professional level. The way it works is by using what are called a suite of sensors, capable software and CNC computerized controls to adjust as needed throughout the printing process, leaving little room for error. These monitor the metal deposition parameters from beginning to end ensuring the desired uniformity and variations are adequately achieved. It´s an effective feedback system that works with carefully developed algorithms to quantify everything that is being done.

EBAM is a marvel of sophistication and is designed to be extremely precise by adjusting deposition parameters to a T, be they electron beam power input, the rate of wire feeding, and CNC motion profiles that allow for optimal orientation. Seeing it in action is quite a thing as it is also one of the fastest working machines, printing with a rate of deposition that ranges from 7 to 20 pounds of metal per hour. Applications for this technology are mind expanding and simply make sense if you´re looking to make more with less, for instance less specially skilled personnel and less industrial space. EBAM can build parts up to 19 feet in length at a high speed, for example 15 pounds of titanium per hour. This means a reduced lead time and costs of material reaching up to 80% in savings, which is sure to help a commercial business´s bottom line.

It takes a lot to develop 3D printers at this scale, particularly as it is a new territory and there is plenty of room for mistakes. This is especially true when it comes to the complexities that are involved in metallurgy. It is because of this that it helps a lot to have a large company backing you up. Established in 1939, Sciaky is a prime example that has been a manufacturer of welding and 3D printing services systems for a long time and has spent years building on top of previous expertise in the field. It was a key supplier for warplane components during the second world war and has been in a prime position to innovate in what some would correctly call a limited 3D printing market. Companies like these have been working on new manufacturing methods without much public attention. In 1957 Sciaky Inc. produced the first Electron Beam welding system ever and it isn´t until now that industrial commercial applications have emerged.

GE Additive: Making Strides In Industrial Metal 3D Printing Services

Another example is General Electric which has announced plans to produce an industrial laser printer that´s meant to manufacture structural components and single-engine plane parts to begin with, but with interest in expanding to the gas, power and oil industries as well. There are many applications indeed and GE Aviation is leading the way through its aviation division and up to now has already been printing up jet engine fuel nozzles and even the very first commercial aircraft engine in history to have a large portion of components that are made through additive manufacturing. This is sure to prove time saving and efficient as 855 disparate parts may be brought down to just 12 that are carefully designed. There are many possibilities for growth. GE Additive is a testament to that as recently it has acquired German company Concept Laser and has been utilizing their technology to make huge wing brackets with little assembly required. It is thanks to the incorporation of Concept Laser expertise that GE has announced that it is working on the aforementioned world´s largest laser based metal powder bed metal printer.

Metal 3D printing services are growing thanks to big strides in innovation. We just have to ask ourselves how big can we really dream?