3D Laser Scanning Technology.

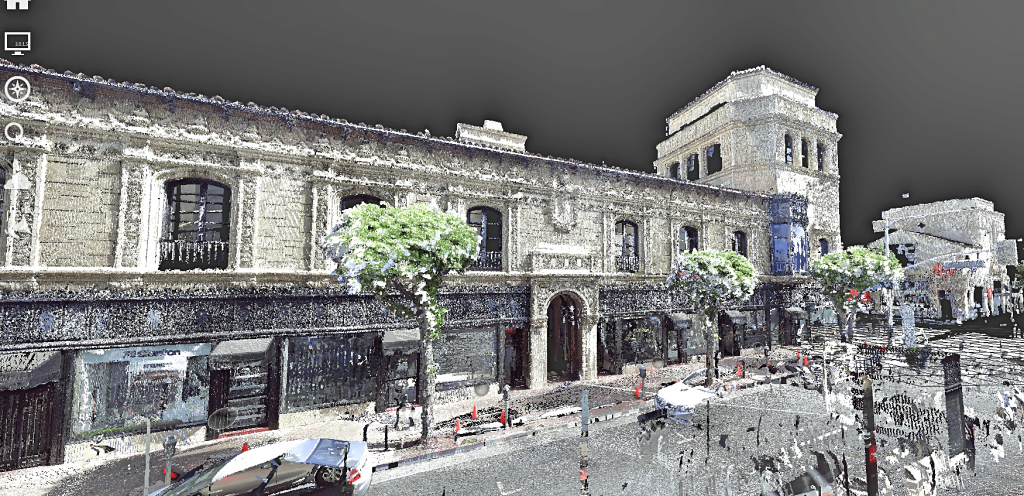

If you are not familiar with the term “3d laser scanning”, it may bring to mind barcode scanning or body scanning at the airport. While a 3D laser scanner may look a little like alien technology, it is in fact a very down-to-earth combination of electronics and precision optics packed into a robust, portable unit. 3D laser scanning creates a digital representation of a physical object in the form of a point cloud which can later be converted into a 3D model.

What is 3D laser scanning?

In simple terms, 3D laser scanning is a non-invasive and non-destructive method to collect measurement data. It captures the shape of physical objects, buildings, infrastructure, etc. using pulses of laser light. As the scanning is in progress, it stores the measured points in files called point clouds. The laser light is able to capture any free-form shape within its range, to a surprising level of fine detail.

3D laser scanning the industry standard method for capturing the exact shape and size of a building, power plant, or very large object. Using 3d laser scanning is much better than the old fashioned method of taking hand measurements. 3D laser scanning is able to improve the engineering and design process by speeding up measurement tasks and reducing or eliminating data collection errors.

3D laser scanners are commonly used for on-site surveying of topography, internal and external building structure, piping, conduit and equipment. They can also be used to audit material inventories. How is this useful for auditing? Let me explain in an example. Dirt and loose materials are hard to measure due to their free-form shape. In the past, measurements were usually done with estimations using height, width and length. Using 3D laser scanning however, we are able to accurately capture the shape of the dirt pile in a 3D model and calculate the volume to a more precise degree. The accuracy of this process makes it suitable for volume calculation of stockpile inventory and auditing purposes.

Why do 3D laser scanning?

There are many reasons:

- Low cost

- Capture large environments quickly

- Save time and money.

- Take measurements directly from the scans

- Create “as-built” or “design-intent” CAD models

- Create CAD models that are compatible with AutoCAD

- Create BIM models in Autodesk Revit

- Create plan and elevation ortho images

- Volume calculation for materials that do not have a regular geometric shape.

- Inspect large structures for defects

Once 3D laser scanning produces 3D model, what can I do with a 3D model

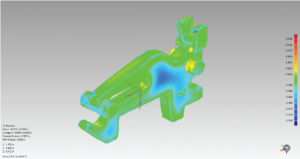

I would assume that if you are reading this, you would like to know more about 3D models. As the saying goes, if a picture is worth a thousand words, a 3D model is worth a thousand pictures. How is that? Well, a 3D model is a digital representation of the object or area. Since it is in digital form, its exact shape and size can be understood in ways not possible otherwise. That’s not all. The 3D model can be modified to make a new product or repair an existing design to accurately reproduce the object by other means such as milling technologies, water jet cutting, rapid prototyping or 3D printing. Or course if you do not want to do any of these things, you can just scan and keep the 3D model for safekeeping as documentation for future reference , knowing that all of the intricate details of the part will never be lost should be part be destroyed. The sky and your imagination is the limit as to what you can do once the object is in its digital form.

Just a thought and a small example here, facial structure can be scanned and the 3D model can be modified to your taste before the actual plastic surgery is done. The best part is, it is probably cheaper, safer and less painful, because going under the knife can be painful to rectify an error. What about the eyes? Some lasers are eye-safe.

Limitations? How big can I go? How small can I go? Lightings? Specific settings?

Great news! With different laser scanners, we are able to scan huge factories to tiny parts and everything in between. Examples of scanning we have done range from the interior and exterior of a State Capitol, monuments, churches and power plants to things as small as a coin, internal parts of expensive watches such as Rolex, separate parts of guns and even dental braces. We are also able to scan complex organic surfaces such as lotus textures.

As to settings, our scanner is able to scan indoors and outdoors, bright or dark areas, and at a wide range of temperature differences. Different scanners are used depending on the fine details required. Our scanners are portable, therefore we are able to scan at the client’s location. But usually if it is small enough, clients are encouraged to ship the item to our nearest office. This is because our offices are better equipped and have better setup to scan things quickly.