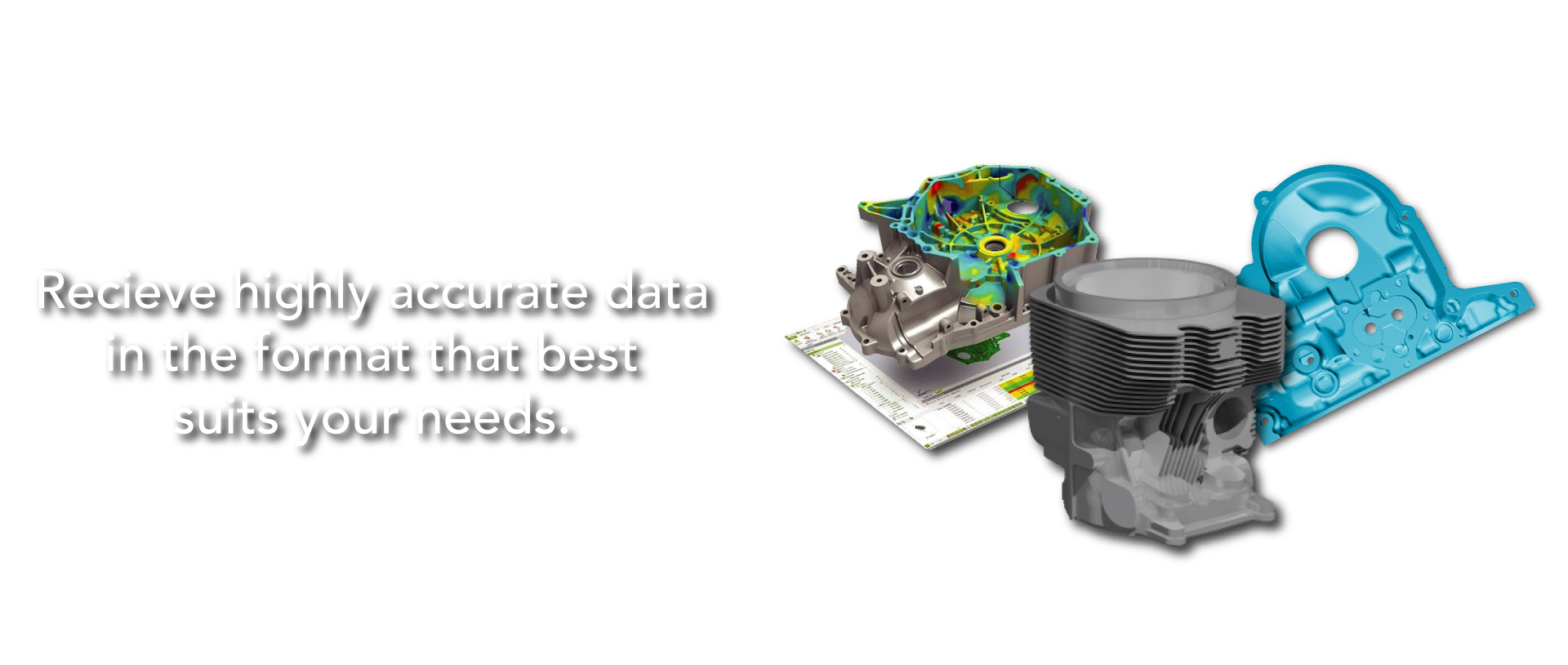

Scan your Part and receive a CAD model

transform, remake, improve with 3d scanning services

what is reverse engineering?

Reverse Engineering refers to the process of re-creating design drawings by taking measurements and/or scans of the part itself. It’s a simple, two-step process: 1) scan the object, 2) create a 3D model of the object.

How is reverse engineering different than other kinds of modeling?

The process of creating a CAD model for reverse engineering services requires some understanding of the original designer’s thought process. For example, one must make assumptions about whether a part is supposed to be symmetrical or perfectly round in shape. With reverse engineering, the goal is often to produce a CAD model of very high quality surfaces, or “idealized”, where faces are perfectly flat, holes are perfectly round and surfaces are all seamlessly blended into one another. This makes it easier to create feature-based models along with dimensioned 2D drawings. This is different than “as-built” modeling, where the goal is to intentionally model a part’s flaws wherever they exist.

Why utilize Reverse engineering services?

Common reasons include:

- 3D scanning for manufacturing

- Replicate a one-of-a-kind part

- Analyze a competitor’s product

- Create machining drawings for a handmade prototype

- Create a nominal model to be compared against for inspection

- Make changes and improvements to a product’s design

- Preserve and document handmade molds & obsolete parts

- Blueprint parts for government certification

- Create the mold for a part

What can you do with a 3D model created by reverse engineering services?

Because of the high quality models produced during the reverse engineering process, the models happen to be very versatile. Among the many things that are possible:

- Machining & molding

- 3D printing

- Making changes to the design

- Patent drawings

- Exploded 3D visualizations and animations

- Comparisons with other parts or scans

- Can be used to design mating parts or packaging

- Drawings can be sent overseas for manufacturing instead of the part

Alternatively, you can just keep the 3D model for safekeeping as documentation for future reference knowing, should the part ever be lost or destroyed, that you have sufficient information build another one. The sky is the limit as to what you can do once the object is in its digital form.

Are there limitations on size?

Great news! With different laser scanners, we are able to scan huge parts to tiny parts and everything in between. Examples of scanning we have done range from windows and large monuments to things as small as a coin. We are also able to scan complex organic surfaces such as an artistic human bust.

Different scanners are used depending on the application. Most of our scanners are portable, therefore we are able to scan at the your location. But if your item is small enough, it is usually cheaper to ship the item to one of our scanning offices. This is because our offices are set up to scan items quickly and economically.

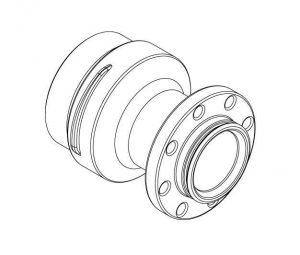

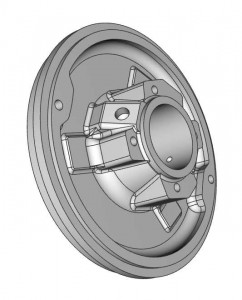

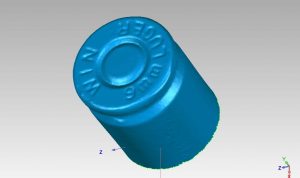

more examples of reverse engineering

Here are some simple reverse engineering services we provided for clients.

Do you have a part to reverse engineer?

Reverse engineering projects start at around $500. We’d love to hear more about what you are working on. Contact us today.