3D Scanning Services for Custom Part Fabrication

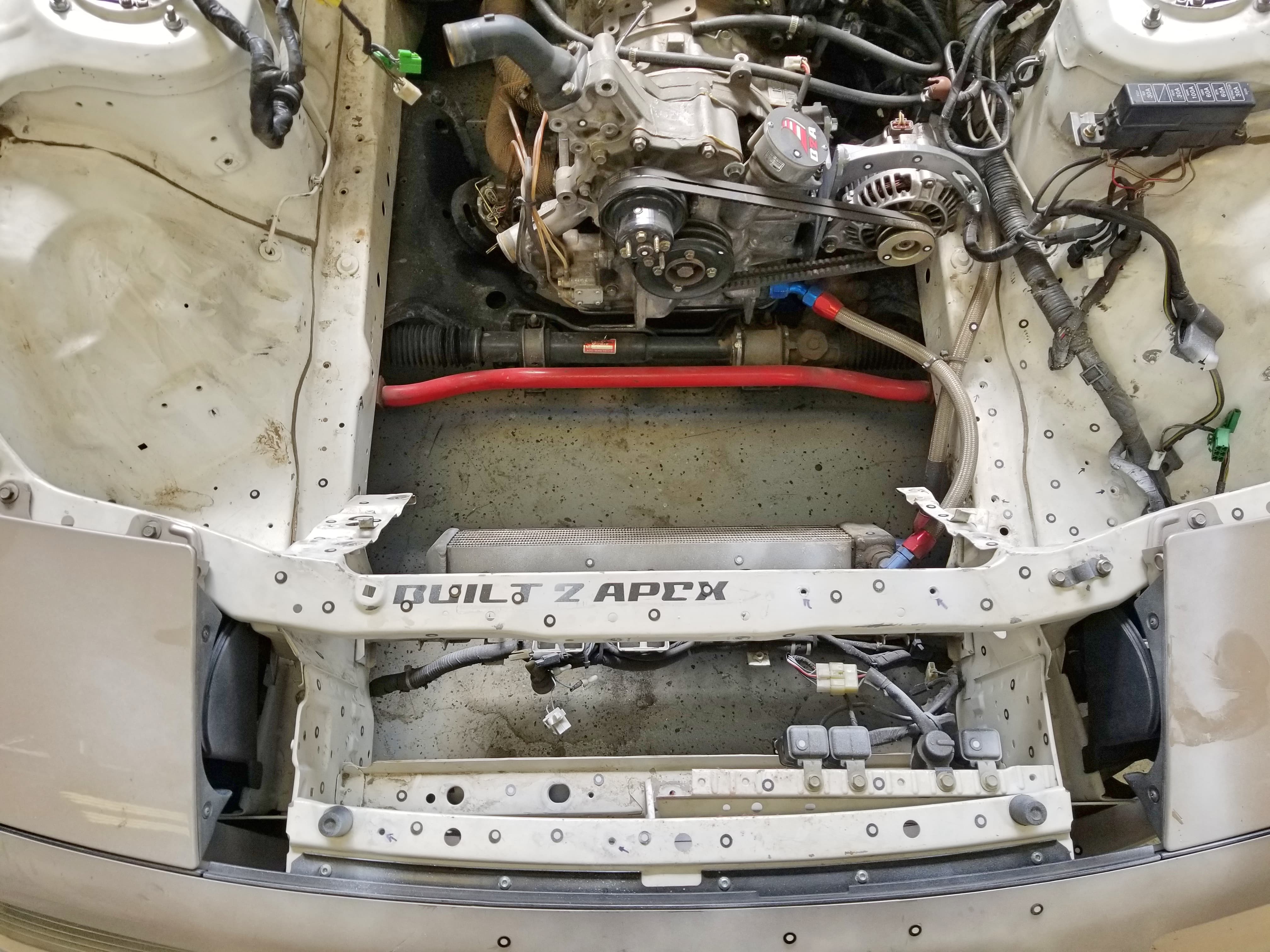

The automotive industry has been one of the leading industries that constantly relies on highly accurate 3D data to do inspections, reverse engineering and custom fabrications. Recently we were contacted by our friends over at Built2Apex for some more automotive scanning in preparation for a race and trade show. They were looking to do some custom fabrication to the front bumper and engine bay of their race car and needed accurate point data. Thats where we come in. Equipped with out Creaform Go!Scan, our scanning technician was able to quickly scan the interior of the engine bay and exterior bumper and deliver the data to them in the same day.The Right 3D Scanning Service for any Situation

Once the bumper and engine bay scans were complete, we were given 2 more custom fenders to scan. For the fenders, scanning with the Faro arm was the ideal choice considering the edges and bolt pattern data required. With both fenders, bumper and engine bay completely scanned, Built2Apex can now complete the custom fabrication to their race car and hopefully win their race. This was a great example of the multiple ways that we can help you with your project. No matter the job, we have the right technology and experience to give you the best results. For more information regarding Built2Apex, click here. For more information regarding our 3D scanning services and how we can help you on your current and upcoming projects, click here. For any and all of your 3D scanning needs, Arrival 3D has you covered.