Fast & Accurate 3D Laser Scanning in Tulsa and Oklahoma City

Scan-to-CAD in Record Time

Offices Nationwide

Guaranteed Results

Thousands of Successful Projects

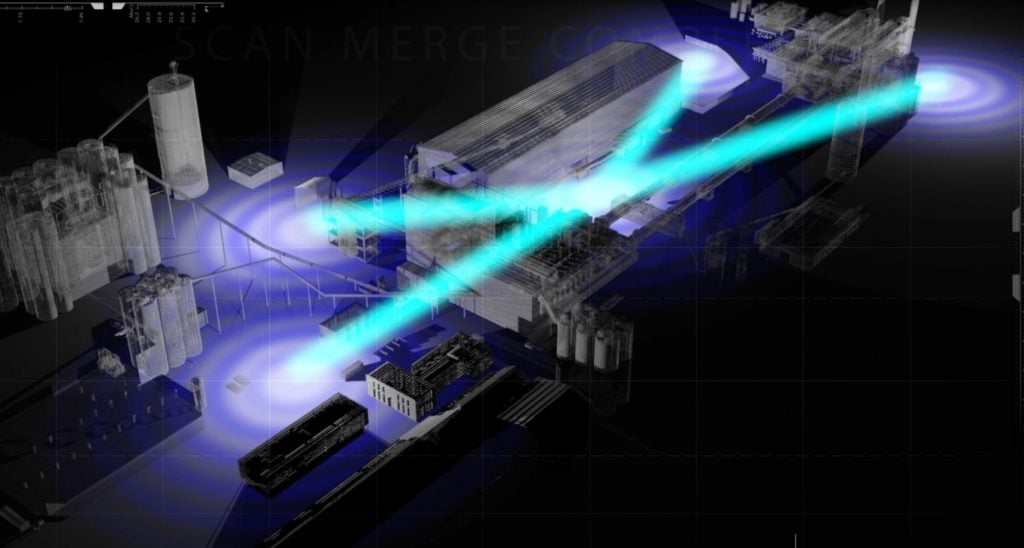

World-class 3D laser scanning in Tulsa and Oklahoma City

Capture your facility with incredible speed and accuracy and receive a CAD model.

Get A Free Quote

Why hire us for Oklahoma 3D laser scanning?

- We cover the entire USA

- We use the latest lidar reality capture 3D laser scanners

- Quality control and on-time delivery are paramount

- Your satisfaction is guaranteed

Is this your first time using 3D Laser scanning in Tulsa and Oklahoma City? Here are a few articles that you may find helpful

Tulsa Oklahoma 3D Laser scanning solves problems like:

- Easily obtain an as-built CAD model where none existed before

- Perform simulation and analysis

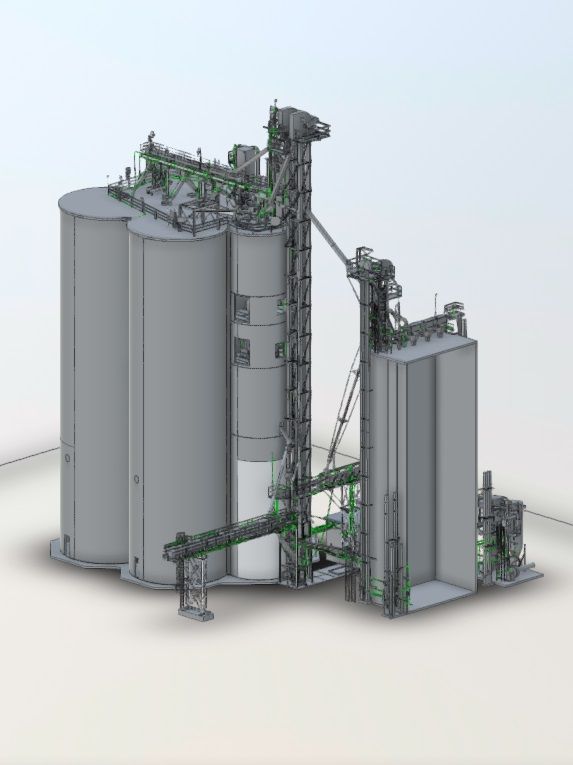

- Analyze whether something is flat, such as a floor or wall, or round such as a tank

- Create a full set of 2D and 3D drawings

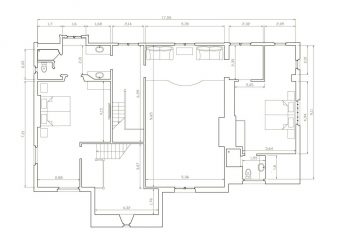

- Create an As-Built Revit model for building renovation

- Create a digital twin of your facility

- Plan the floor layout during a renovation or restoration

- Capture the exact shape of something to analyze it for flaws

How much can be scanned in a day?

It is possible to scan vast amounts of space in a single day. Examples include:

1) The entire engine room of a huge sea going vessel

2) A 10,000 sq. ft luxury home

3) A large 2-story office building

4) A small oil storage terminal

5) Large sections of an industrial plant

But capturing the necessary level of detail is equally important to covering large areas. That is why it is important to optimize the scanning process to get most coverage possible in a day while being careful to capture the necessary detail. We can help you determine the necessary level of detail by asking simple questions such as “What is the smallest object you need to see in the scan?” Another way of asking is, “What is the smallest pipe or conduit diameter that you want to appear in your CAD model?” If the answer is 1″, the scanning strategy must be different than if you answered 4″. Our commitment to you is to strike the best balance between coverage and detail so you get the most scanning for your dollars.

Some applications of 3D laser scanning in tulsa and Oklahoma City:

Renovating an old multi-story building

When planning and engineering for multi-million dollar projects such as a large building renovation, it is critical that things go right. 3D scanning up front allows engineers to draw up precise plans and drawings that minimize conflicts during construction. The scan serves as an invaluable resource for many interested parties in such a project.

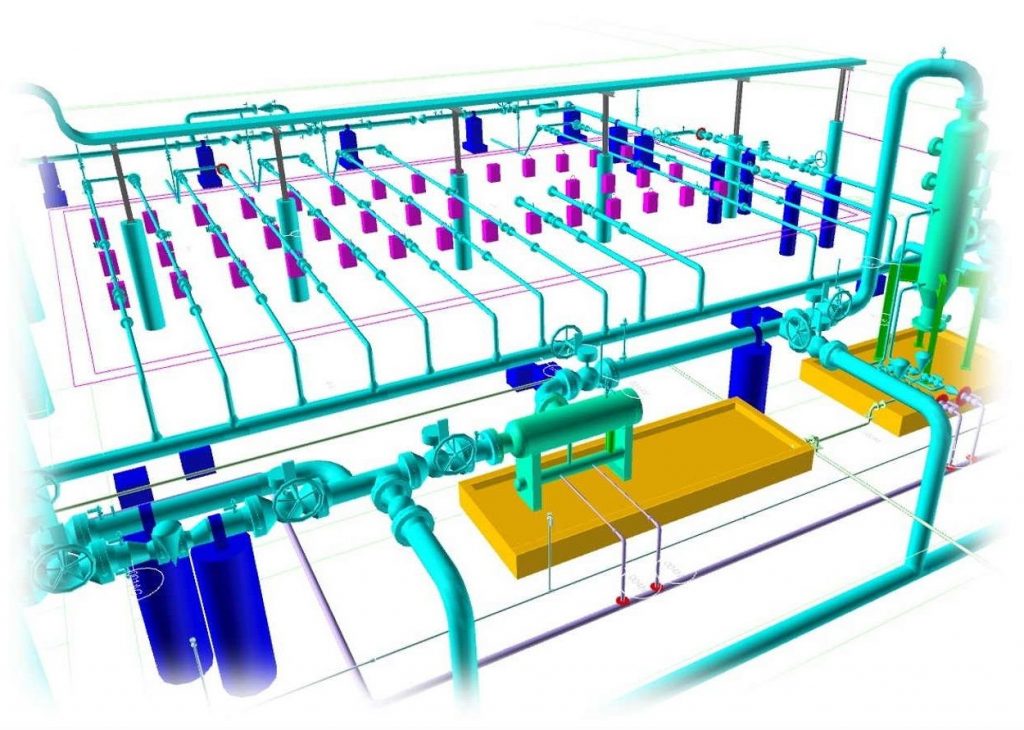

Update P&ID's for a gas plant

A plant in the oil and gas industry will change over time, that is without question. This results in the P&ID drawings of record ultimately becoming out of date. 3D laser scanning provides a dual benefit of not only providing a way to update P&ID’s but also provides a truly accurate as-built reference 3D model of the plant. We feel that an as-built 3D model combined with smart P&ID’s is the way of the future.

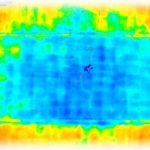

measure floor flatness

3D laser scanning provides a better way of measuring and visualizing floor flatness than the old FL and FF method as measured with a ruler. When you use a 3D scanner you get extremely thorough and accurate results that can be depicted as color maps for a deep understanding of the floor’s shape.

obtain a 3d model of an aircraft

Scanning an airplane is a fantastic way to capture it’s shape. We can scan interior and exterior and convert it into a CAD model or STL mesh depending on your needs. From small single seaters to airliners, we are the best at aircraft 3D scanning and would be delighted to scan an aircraft for your company.

determine whether something will fit

You may have a pump that you need to lower into a channel, and you want to see if it will fit before lowering it in and getting stuck. Or perhaps you have a large vault door that hasn’t been opened in years, and you want to know if it will scrape the concrete. 3D scanning can answer these questions so you can proceed with confidence.

Obtain as-built models of a power plant

Many power plants have outdated as-built drawings. 3D scanning provides a way to obtain updated drawings in the form of 3D CAD models of structural steel, ducts, equipment and piping. Armed with accurate models, your engineers can route new designs around existing objects, avoiding potential clashes and interferences during new construction.

Design to fit existing pipes, vessels and equipment

When a processing plant adds a new product line, there is new piping and equipment that needs to be installed. With careful planning and the as-built drawings obtained from doing 3D laser scanning, the new piping designs can be engineered for precise fit, minimizing installation delays due to unforeseen conflicts.

as-built reference for boats, ships & vessels

3D laser scanning can capture the exterior or interior of a sea-going vessel. Any sized boat, ship or vessel can be scanned. For smaller boats (depending on location) this can be done in a day. The scan can be turned into 2D drawings for use by a naval architect, or into 3D solid models for various types of analysis.

analyze wind turbine towers for defects

Wind Turbines can be scanned safely and easily from ground level. Scans can be used to analyze to identify any dents that may be present, and map out their location and depth. Scans can also be used to analyze the tower has a whole, and determine whether it has been structurally compromised after a failure event.