what is 3d scanning?

The concept of 3D scanning

3D Scanning has myriad essential applications in the world we live. 3D Scanning is a key initial technology in the process of 3D Fabrication as it enables key 3D data to be referenced prior to CAD Modeling in the course of both new product development and the development of modifications to existing structures & product. 3D Scanning then enables 3D data post development in quality & compliance processes.

It is most common for us to visualize 3D data in “space” via a 3D grid system. From a “Zero” datum (a fixed point from which all data can be referenced), we can project outwards an X,Y,Z measurement model. X is lengthways, Y is width, Z is height. Most of humanity’s great structures throughout time feature a combination of horizontal and vertical elements, these structures will have required forethought & spacial planning and will have utilized a similar system. Without a fixed or otherwise referenced datum/s, 3D data can have no control or meaning.

3D Scanning is performed and the outcome is 3D file datapoints. This file can be saved, edited and even recreated in physical form using 3D printers.

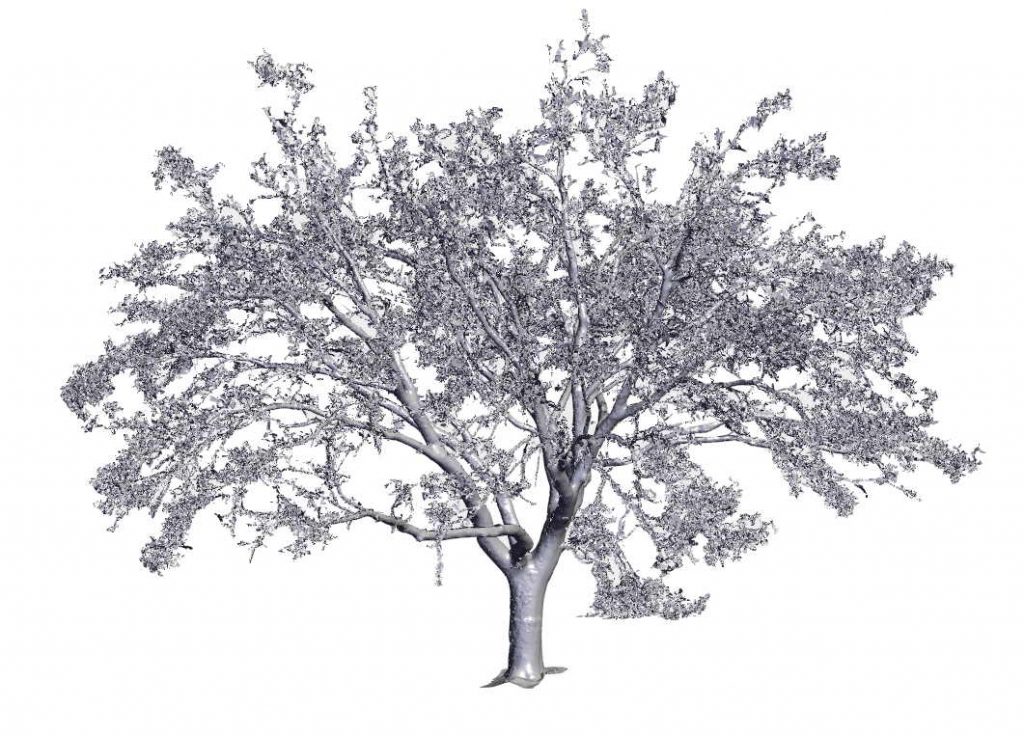

Importantly, the data output is “point cloud” which is non-geometric. Point cloud data is basically “as scanned” surface data, converted to a mesh or polygon based surface. This data is non-geometric and useful reference as is, however in many product development applications it will be imported into 3D Modeling software and used to facilitate correctly engineered, geometric surface data.

3D Scanning History

3D Scanning was first developed in the latter half of the last century as a means to recreate, in 3D data,

surfaces of objects & places in order to facilitate developments & improvements. The concept of mapping datum points in space is fairly simple. The methods by which to generate this data and the accuracy of that output however, has seen significant development since.

This development has embraced multiple new technological developments over time. Early approaches looked at physical “touch” to generate data or a combination of lights, cameras and projectors. While broadly successful, these systems required great effort & time.

Technological developments continued apace in the years to come. The 1980’s witnessed the introduction of lasers, which have become the predominant technology to date. Optical technology became the preferred model for 2 primary reasons; Touch scanners, which are still in use today, are limited by reach of touch & are problematic in respect of soft or fragile surfaces. Optical technology has greater range, can capture immense amounts of data in just seconds and enables capture of additional elements like color & graphics (Referred to as “Texture”).

Of the optical data collection methods, “stripe” excelled in data capture and remains in use today. Stripe technology passes over a surface using multiple points of reference to measure surface area from. Accurate, rapid levels of data capture result. A continuing area of development relates to the fact that lasers see only what they can reflect from a single viewpoint. Laser light, of course, can’t turn corners.

For this reason it’s been necessary to scan any 3D object from multiple viewpoints in order to fully capture a 3D form. Subsequent scans must be accurately matched (a process referred to as “registration”), to create a complete, integrated file comprising multiple scans. In recent years development focus has been multi-layered; software and computing power enables data collection from multiple viewpoints, including the use of drones. Registration is no longer a manual process. AI is

being introduced to 3D Scanning to enable the process to become both fully automated & increasingly user friendly.

3D Scanning Applications

3D Scanning is integral to the process of 3D

fabrication. Designers, engineers & various technical roles utilize this

technology for useful 3D spacial reference in the course of developing new 3D

developments. 3D Scanning will continue to

play an increasing role in the fields of Quality Control, Scanning of hand

sculpted designs, Scanning of biological non geometric forms including the

human body as well as myriad other applications. It is now the case that even

mobile devices such as cell phones and digital cameras are beginning to offer

scanning capabilities to consumers.

Besides applications listed below, all of these industries

utilize 3D Scanning for the purposes of 3D

Modeling.

Automotive 3D Scanning to constantly update surface changes

in 1:1 clay models for comparison to existing digital engineering & design

files.

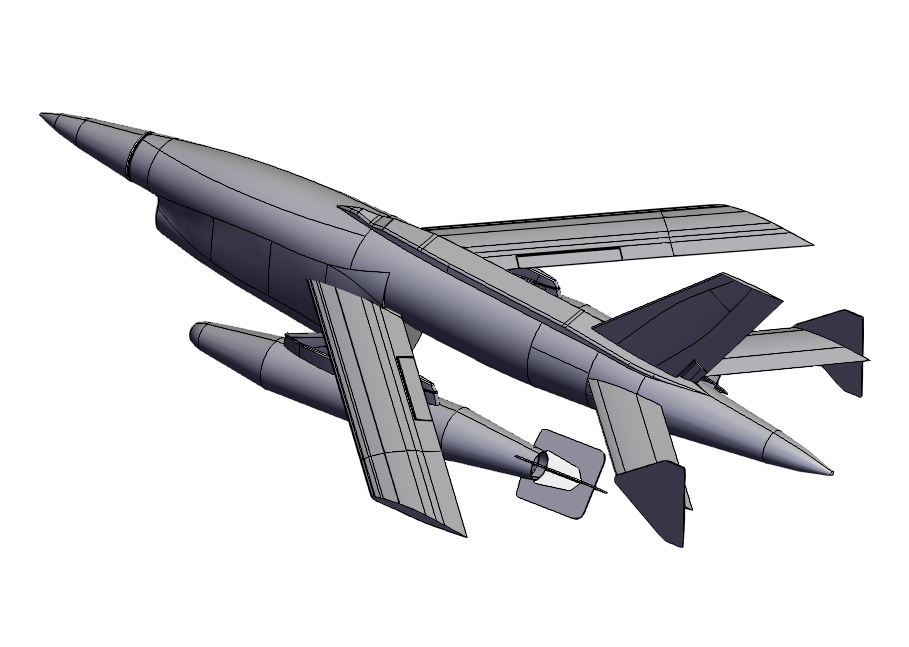

Aeronautics | Multiple applications |

Architects | 3D |

Medical | 3D |

Dental | 3D |

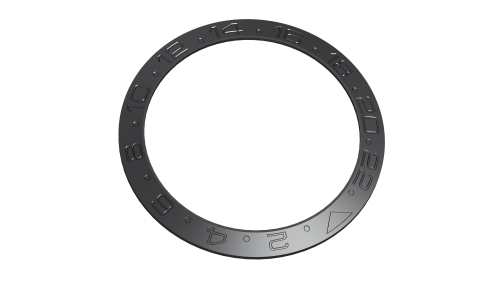

Jewelry Making | 3D Scanning |

Video Gaming | 3D Scanning |

Special Effects & Animation | 3D Scanning Location & Environment for Virtual Camera 3D Scanning of static 3D |

Reverse Engineering | 3D |

Quality Control | 3D |

Quality Control 3D Scanning is routinely used in pursuit of quality control. 3D Scanning can rapidly assess conformity in both

new product production & in-service equipment, whereby scans are created of

3D surfaces and efficiently compared to digital “master” data. Where errors in

surface, beyond specified tolerance exist, scanning becomes an invaluable

quality control tool.

3D Scanning Technologies

3D Scanning has evolved a number of successful formats, each suited to a variety of applications:

- 3D Scanning via Laser Triangulation such as with CMM arm scanners

- 3D Scanning via Structured Light, such as with Portable Handheld Scanners or Turntable-type structured light scanners

- 3D Scanning via Photogrammetry

- 3D Scanning via Touch Sensors (Digitizing)

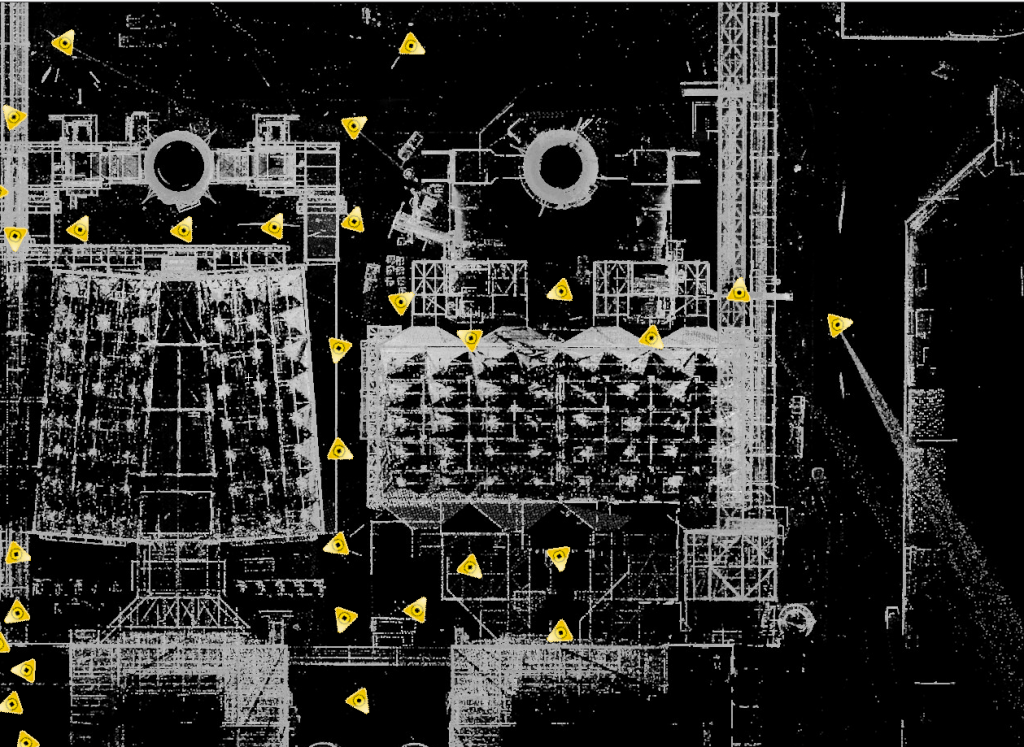

- 3D Scanning via Laser Pulse (Time-of-Flight / Lidar)

Accuracy vs. resolution

Scan accuracy varies considerably between technologies, and higher accuracy comes at a higher cost. The subject to be scanned, the scanning environment & the resolution and accuracy required of a 3D Scan output file will contribute to a determination of which technologies present the best solution for the task. Besides the accuracy between measured points and their actual location, scanners also vary in terms of resolution, which is the distance between captured points at a given scanning distance. This means details on the scanned object that are smaller than the scanner’s resolution won’t be captured.

3D scanning volume and coverage

3D Scanning technologies vary greatly in respect of area that a scanner can successfully capture.

Desktop scanners are suited to smaller objects. Handheld scanners can be manually moved around the subject and have fewer size constraints than desktop models. Handheld scanners, depending upon cost, have much greater range, can scan instantaneously and can capture precise measurements. Handheld scanners are ideally suited to taking human measurements (where the subject is not perfectly still) for ergonomics and medical applications. Some scanners utilize a single axis turntable from which to rotate the subject. For further accuracy, some scanners have the ability to move the subject around multiple axes, capturing scan data from multiple angles. This feature can be a requirement for complex objects with deep recesses whereby scan data captured from multiple angles becomes an imperative. If an area of the model can’t be seen by the scanner it will cause a void, or occlusion, in the scan data. These issues are easily repaired within most scanning software however these patches are rarely accurate to the physical surface properties.

Projects involving a larger scope will often be addressed by Laser Pulse (Time-of-Flight/Lidar) 3D Scanning. Precision can be adjusted per application, however, very high resolution and quality settings generate very large 3D Scanning files.

Laser triangulation 3d scanning

A single laser beam is projected onto a surface & the change in the trajectory of the projected laser beam is recorded by a sensor.

This data is combined with a distance reading (of the scanner to surface) and, via trigonomic triangulation, a continuous data file of the surface may be recorded.

The change in trajectory of the laser beam combined with the distance from surface position of the sensor is calculated via trigonomic triangulation formula which, combined with the position of the scanner enables continuous mapping of the surface to a 3D scanning data file.

Advantages | Laser Triangulation 3D Scanning enables high resolution & accuracy. Accuracy in the range of 0.1 mm or better is possible. |

Limitations | Laser Triangulation 3D Scanning laser beams are at times sensitive to shiny & transparent surfaces. |

3d scanning via structured light

Structured Light 3D Scanning measures the pattern of light deformation upon a surface. Light is projected in linear patterns onto a surface and the scanner analyses the edge of each line as it makes contact. This data is combined with a distance reading (of the scanner to surface) and, via trigonomic triangulation, a continuous data file of the surface may be recorded.

Structured light is generally white or blue, is generated via the use of Digital Light Processing (or similar) projectors and is either a series pattern or dot matrix.

Advantages | Structured Light 3D Scanning enables both high resolution & speed and is effective for Human Body Scans. Structured light can achieve higher accuracy than laser scanning due to the noise caused by laser speckle patterns. In general, structured light scanning provides the best resolution and accuracy, typically slightly higher than laser scanning. |

Limitations | Structured Light 3D Scanning is sensitive to lighting conditions and is difficult to use effectively outdoors. |

3d scanning via photogrammetry

As the name suggests, this technology records multiple photographs of a static subject from multiple angles then, via computational geometry algorithms and computer vision, the photographs of the subject are reconstructed into a 3D form. Parameters including focal length and lens distortion are required, then pixels in corresponding images are automatically detected from which an accurate 3D model is be created. Under ideal conditions, object detail captured by photogrammetry can rival a laser scanner, however, geometric accuracy is usually worse due to the lack of fixed reference points for the camera’s position.

Advantages | Photogrammetry 3D Scanning will reconstruct large or small subjects photographed from the ground or the air with precision. |

Limitations | Photogrammetry 3D Scanning requires significant computing power to process multiple images and to cross reference pixels within each to create 3D data. The system is sensitive to image resolution and algorithmic processing can be time consuming. |

3d scanning via touch sensors (digitizing)

Touch sensor scanning involves either a moveable probe attached to a measuring device capable of spanning a desired area while recording its position in space. Conversely, a static probe with a moveable object can be employed. As the probe makes contact with the subject deformation triggers point recognition. 3D data is built up over time until a complete picture is generated. CMM’s (Coordinated Measuring Machines) fall into this category of scanners.

Advantages | Touch Sensor 3D Scanning (Digitizing) is precise and effective upon both reflective & transparent surfaces. |

Limitations | Touch Sensor 3D Scanning (Digitizing) is problematic in respect of soft, deformable surfaces and is time consuming. |

3d scanning via laser pulse (time-of-flight or phase-shift lidar)

Laser Pulse 3D Scanning relies upon the travel time of a Laser from source, to subject, then reflected back to a sensor, to calculate the geometric contours of a surface. The speed of light is a known unit of measure and so by measuring the interval time between the emission and the reflected return of a laser beam to the scanner, accurate measurements can be generated.

The scanner will employ a single laser, firing laser pulses on a pico-second (0.000000001 seconds) frequency. The laser pulses are reflected from a rotating mirror mounted upon a 360’ rotating scanner unit. The resulting array of laser pulses reflect a single data point each from the environment and a comprehensive 3D data file is the result.

Precision can be adjusted per application, however, very high resolution and quality settings generate very large 3D Scanning files.

Advantages | Laser Pulse 3D Scanning (Time-of-Flight / Lidar) is accurate & suited to large scale scanning applications. |

Limitations | Laser Pulse 3D Scanning (Time-of-Flight / Lidar) laser beams are at times sensitive to shiny & transparent surfaces. |

3d scanning with consumer mobile devices

3D Scanning is a comparatively new capability of mobile phones. Increasingly, 3D Scanning features will be fully integral features, per the Xperia XZ1. Currently, it is more common to download a 3D Scanning App such as 123D Catch from Autodesk or Kinect from Microsoft. Having decided upon an App, directions are simple; Select the subject, be sure that access around the subject is uninterrupted and that lighting conditions are even throughout. Initiate the scanning procedure, 3D Scanning all facets around the object while maintaining a constant distance between the phone and the subject. 3D Scanning sensors within the phone then collect & process data. The output file may be exported to a wide number of applications from use as an Avatar in a Virtual Reality environment or game, through to 3D Printing.

post-processing of 3d scanning data

Touch sensor 3D Scanning (Digitizing), captures very manageable amounts of data, however, Laser & Light based 3D Scanning systems capture very large amounts of data per file. For many projects, multiple scans from a number of viewpoints will be required resulting in multiple, large & related files. If multiple related files are collected, they will first be aligned via “registration”, one to the other, to form a complete 3D picture. These combined scans will then be optimized by deleting excess data and then “repaired” (dependent upon application) by filling holes etc. Ultimately, the file can be exported into a number of standardized file formats including PLY, OBJ, STL, ASC, FBX. for downstream use.

Some 3D Scanners have fully integrated post-processing capabilities however, additional advanced post-processing software may be required for other industry applications including reverse engineering and quality inspection. Due to the large size of the files created, powerful computing capability saves valuable time. It is also possible to combine data output from a variety of types of scanners into a single output file.

It is important to capture high quality raw data during the acquisition stage because post processing will typically clean data and reduce file size, reducing overall resolution and quality. The offset here is that high quality resolution at the data acquisition stage is potentially very time consuming. An experienced technician, aware of the resolution ultimately required by the client, will be knowledgeable and experienced in the compromise required between time spent in data acquisition, and the required quality of the end product.

The future of 3D scanning: market projections thru 2025

3D Scanning will see continued growth in coming years as both industry & consumer demand continues to increase.

Allied Market Research report in September 2018, that the global 3D Scanning market was valued at $8,427.0 million in 2017, and is projected to reach $53,345.0 million by 2025, registering a Compound Annual Growth Rate (CAGR) of 25.7% from 2018 to 2025. North America was the highest contributor to the global market, with 39% of the market share in 2017, registering a CAGR of 23.1% during the forecast period 2018-2025.

Allied Market Research September 2018

Markets & Markets report in July 2017, that the 3D Scanning market is expected to grow from USD 3.76 billion in 2017 to USD 5.90 billion by 2023, at a CAGR of 7.8% during the forecast period. The market growth can be attributed to the increasing need to capture large volumes of 3D data for modeling and analysis, rising focus on quality control, and growing awareness about advanced medical treatments.

Markets & Markets July 2017

This data refers to 3D Scanning Market by:

• Type (Optical Scanner, Laser Scanner, and Structured Light Scanner),

• Range (Short Range Scanner, Medium Range Scanner, and Long Range Scanner),

• Service (Reverse Engineering, Quality Inspection, Rapid Prototyping, and Face Body Scanning), and

• Application (Entertainment & Media, Aerospace & Defense, Healthcare, Civil & Architecture, Industrial Manufacturing, and Others)

Key 3D Scanning developers include: Faro Technologies, Inc., Creaform, Inc., Direct Dimensions, Inc., GOM mbH, Konica Minolta, Inc., 3D Digital Corporation, Autodesk, Inc., 3D Systems, Inc.

The above reports into the future of 3D Scanning identified the following key considerations in respect of future growth:

5. 3D Scanning is playing an integral role in shortening product development and manufacturing times by streamlining the QA/QC process.

6. Ongoing technological advancements concerning portability, scanning range & image quality are opening new application areas for this equipment.

7. Increasing demand in the 3D Printing market, high definition content recording for movies and historical site preservation by 3D Scanners are some of the factors that are expected to create lucrative growth opportunities during the forecast period.

8. 3D Scanners that use any combination of laser triangulation, phase shifting, time-of-flight technologies are expected to hold the largest share of the market, due to ease of use and wide availability.

9. The portable coordinate measuring machine (CMM) segment of the 3D Scanner market, which includes handheld and articulated arm CMMs—is expected to grow at the highest CAGR during the forecast period. Not surprising, given the versatility of portable CMMs, which enable users to scan tight spaces with high accuracy.

10. The close relationship between 3D Printing and 3D Scanning means that growth in the former market is likely to spur growth in the latter as well. Moreover, 3D Scanning applications far outstrip those of 3D Printing, at least for the foreseeable future.

11. Most 3D Scanners remain expensive, a major restraint toward the adoption of these scanners.